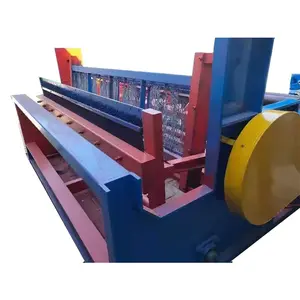

Introduction to Wire Mesh Screen Machines

Wire mesh screen machines are integral components in the fabrication of wire mesh, a versatile product with applications across various industries. These machines are designed to cater to the production of wire mesh by weaving or welding, ensuring consistency and precision in the mesh patterns.

Types and Applications

There is a diverse range of wire mesh screen machines tailored to specific production needs. For instance, fence mesh welding machines are instrumental in creating barriers for properties, while roll mesh welding machines are essential for constructing reinforcing materials in the building sector. In the agricultural domain, machines like chicken cage mesh welding machines are specialized for crafting enclosures for poultry. The adaptability of these machines allows for their use in fabricating products for mining, construction, agriculture, and transportation.

Features and Specifications

When selecting a wire mesh screen machine, several features are to be considered. The wire diameter, mesh width, and mesh hole size are critical specifications that vary among machines, influencing the mesh's final use. These machines are engineered for ease of operation, with a focus on automation to enhance productivity. The resulting wire meshes are known for their structural integrity, aesthetic appeal, and smooth finish.

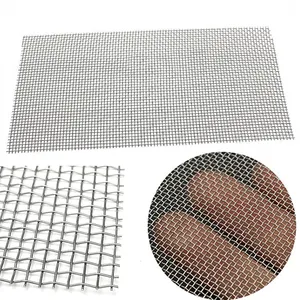

Materials and Advantages

The construction of wire mesh involves various materials, including stainless steel, galvanized iron, or PVC coated wires, each offering distinct benefits. Stainless steel meshes are renowned for their strength and corrosion resistance, making them suitable for harsh environments. Galvanized meshes provide economic advantages and are widely used in fencing and agricultural applications. PVC coated wire meshes are favored for their aesthetic versatility and are often used in decorative applications.

Operational Efficiency

Wire mesh screen machines are lauded for their operational efficiency. The automation within these systems minimizes the need for manual intervention, allowing for continuous production with less downtime. This efficiency is crucial in meeting the demands of large-scale projects and in industries where time is of the essence.

Choosing the Right Machine

Selecting the appropriate wire mesh screen machine requires an understanding of the specific industry needs. Alibaba.com hosts a vast array of machine options, enabling buyers to find the right fit for their production requirements. Whether the end use is for construction mesh, animal cages, or decorative pieces, the platform connects buyers with a global network of suppliers offering machines that cater to a multitude of applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4