Understanding Winding Machine Controllers

A winding machine controller is an integral component in the automation of winding processes used in various industries. This device governs the operation of winding machines, which are essential for creating coils for motors, transformers, and other electrical apparatus. The controller ensures precision and efficiency, managing the speed, tension, and distribution of wire on the coil.

Types and Applications

Winding machine controllers vary in complexity from simple manual systems to advanced programmable options. They are employed in a multitude of settings, from heavy industrial environments to delicate electronic assembly lines. These controllers are crucial for tasks in electrical equipment manufacturing, textile production, and even in the crafting of intricate wire-based components.

Features and Materials

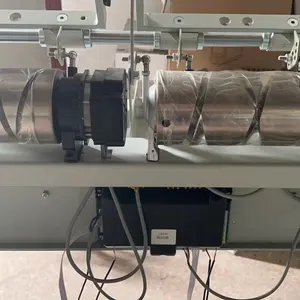

Modern winding machine controllers are designed with user interface considerations, offering digital displays and intuitive controls. They are constructed using durable materials that withstand industrial environments, ensuring longevity and reliability. The internal circuitry is often made with high-grade components to facilitate accurate control over winding operations.

Advantages of Advanced Control

The use of sophisticated winding machine controllers in manufacturing setups can significantly enhance productivity. These devices enable consistent winding quality, reduce material waste, and minimize the need for operator intervention. With features like programmable logic controllers (PLCs), they can be integrated into larger automated systems for streamlined operations.

Selection Considerations

When selecting a winding machine controller, it is important to consider the specific requirements of the application, such as the type of coil, the gauge of wire, and the desired precision. Controllers with memory functions allow for the storage of multiple winding patterns, which is beneficial for operations that require frequent changeovers.

Compliance and Maintenance

Quality winding machine controllers are designed in compliance with international production standards. They require minimal maintenance, ensuring that production lines remain operational with little downtime. It is important to source controllers that come with comprehensive guidelines to facilitate proper usage and maintenance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4