Introduction to Wax Paper Machines

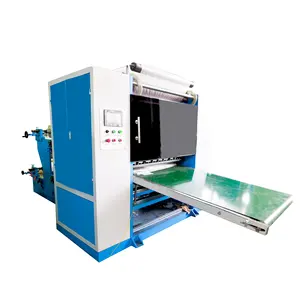

Wax paper machines cater to a variety of industrial needs, streamlining the production of wax-coated paper. These machines are integral in producing wax paper that is commonly used for preserving the quality of food items by providing a non-stick surface. The machinery ranges from basic models suitable for small-scale operations to advanced versions for large-scale production.

Types and Applications

The wax paper machine comes in various configurations to accommodate different production volumes and paper sizes. Applications of these machines are diverse, including but not limited to, the creation of wax paper for Cricut crafting, packaging industries, and food preservation sectors. The adaptability of these machines allows for the production of wax paper that can be used in crafting intricate wax paper stencil Cricut designs or as a protective layer in packaging.

Features and Materials

A wax paper machine is designed with features that ensure efficiency and durability. The construction involves robust materials that withstand the rigors of paper production. These machines typically have a Net Paper Width ranging from 787-900mm and operate at speeds of 20-80m/min, handling paper weights starting from 20-30g/m2. The wax application component is precise, ensuring an even coating on the paper substrate.

Advantages of Modern Wax Paper Machinery

Modern wax paper machines offer significant advantages in terms of production efficiency and environmental considerations. They are designed to consume less energy and reduce waste, contributing to more sustainable production practices. The use of these machines can enhance the quality of the wax paper produced, making it suitable for a variety of uses, including cricut wax paper for detailed craftwork.

Choosing the Right Machine

Selecting the right wax paper machine involves considering the specific needs of your business. Factors such as production capacity, paper width, and machine speed are crucial. Suppliers on Alibaba.com can assist in identifying the machine that aligns with your operational requirements, whether it's for crafting purposes like wax paper Cricut projects or for packaging and food storage solutions.

Sustainable Solutions and Supplier Engagement

Engaging with suppliers on Alibaba.com provides access to a range of new and used wax paper machines, facilitating the selection of equipment that meets your business's sustainability goals. The platform's extensive network allows for the comparison of various machines, ensuring you find one that supports efficient and responsible wax paper production.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4