Popular in your industry

Related Searches:

Top categories

About vacuum emulsifying machine

Vacuum Emulsifying Machine Overview

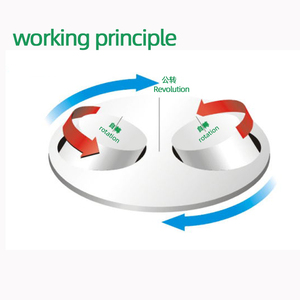

A vacuum emulsifying machine is an indispensable piece of equipment for various industries, particularly in the fields of pharmaceuticals, cosmetics, food processing, and chemical production. This machine is designed to create stable emulsions by blending immiscible liquids under vacuum conditions, which enhances product quality by preventing air entrapment and oxidation.

Types and Applications

The versatility of emulsifying equipment is evident in its various types, such as laboratory, pilot, and industrial-scale models. Each type serves a specific function, from product development in labs to large-scale production in manufacturing plants. Common applications include the production of creams, lotions, ointments, and sauces, where a homogeneous mixture with fine droplet size is crucial.

Features and Materials

Modern emulsifying machines boast features that cater to efficient and hygienic production processes. These include touch screen control panels, temperature and pressure sensors, and advanced homogenizing systems. Constructed from materials like stainless steel, these machines offer durability and compliance with stringent hygiene standards.

Advantages of Vacuum Emulsification

The use of a vacuum emulsifier brings several advantages to production. It enhances the texture and stability of products, reduces particle size for better absorption in pharmaceutical applications, and can improve the shelf life of food products by reducing microbial growth opportunities.

Selection Considerations

When selecting a vacuum mixer emulsifier, it's important to consider factors such as capacity, mixing speed, and the nature of the substances to be emulsified. Additionally, the machine's compatibility with other production line equipment should be assessed to ensure a seamless integration.

Operational Efficiency

Efficiency in operation is a key feature of a high shear vacuum emulsifying mixer. With energy-saving designs and automation capabilities, these machines can contribute to a reduction in production time and labor costs, while maintaining product consistency and quality.