Vacuum Die Casting Machine Overview

Vacuum die casting machines represent a specialized category of metal casting equipment that utilizes a vacuum to enhance the quality of the castings. This process is pivotal in manufacturing components with reduced porosity and enhanced mechanical properties, making it a valuable asset in various industrial applications.

Types and Applications

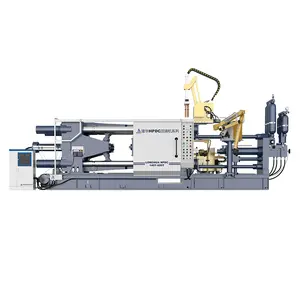

The assortment of vacuum die casting machines includes various models tailored to meet the diverse requirements of the casting industry. From small-scale operations to large industrial tasks, these machines serve a broad spectrum of applications, including automotive parts, precision components, and high-strength enclosures.

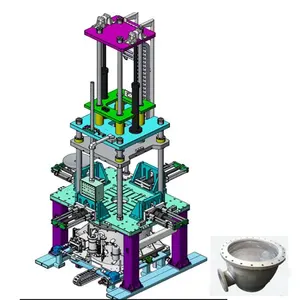

Technical Features

Each vacuum pressure casting machine is designed with specific features to handle different materials and die casting processes. The technical sophistication of these machines allows for precise control over casting parameters, ensuring consistent production of high-integrity castings.

Materials and Durability

Constructed from robust materials, vacuum die casting machines are engineered to withstand the rigors of the casting environment. The durability of these machines minimizes downtime, ensuring a steady workflow in the production setting.

Advantages of Vacuum Die Casting

The use of a vacuum die casting machine brings forth numerous advantages, such as improved structural integrity of the cast parts and a cleaner production process. This method is known for producing castings with finer details and superior surface finishes compared to traditional die casting methods.

Operational Efficiency

Operational efficiency is a hallmark of the modern vacuum die casting machine. With designs focused on user-friendly interfaces and low maintenance requirements, these machines are a staple in settings that value productivity and reliability.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4