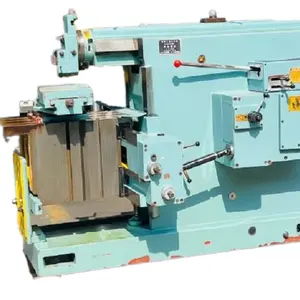

Discover the Versatility of Used Shaper Machines

Shaper machines, integral to various industries, are designed for cutting, shaping, and finishing metals and other materials. The category of used shaper machines encompasses a range of equipment that has been previously owned and operated, offering a cost-effective solution for businesses looking to expand their capabilities without the expense of brand-new machinery.

Types and Applications of Shaper Machines

Within the realm of shaper machines, there are several types, each suited to specific tasks. A used woodworking shaper is a boon for carpentry, adept at cutting intricate shapes and profiles. For those in metalworking, a metal shaper used for precision shaping is indispensable. The small wood shaper, on the other hand, is perfect for smaller workshops where space is at a premium, yet efficiency cannot be compromised.

Features and Materials

The construction of shaper machines often involves robust materials capable of withstanding rigorous use. A wood shaper spindle is typically made from hardened steel, ensuring longevity and consistent performance. Similarly, wood shaper bits are designed from high-grade materials to maintain sharpness and precision over many cycles of use.

Advantages of Opting for Used Equipment

Opting for a used shaper origin machine can lead to significant cost savings, allowing for a lower initial investment while still acquiring a machine that meets production needs. Additionally, a shaper origin used in another facility might come with valuable wear-in that can actually enhance performance, as certain components require a break-in period to achieve optimal operation.

Environmental and Safety Considerations

When selecting a used wood shaper, it's important to consider the environmental and safety features. Many used machines come with built-in safety guards and emergency stops, ensuring operator safety. Moreover, by purchasing used equipment, businesses contribute to a circular economy, reducing waste and the need for new resources.

Choosing the Right Used Shaper Machine

In conclusion, when selecting a used shaper machine, it's crucial to assess the specific needs of your operation. Whether it's a wood shaper grizzly for heavy-duty woodworking or a more general shaper for versatile shaping tasks, the right machine can enhance productivity and contribute to a more efficient workflow. Prospective buyers should consider the condition, specifications, and compatibility with existing processes to make an informed decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4