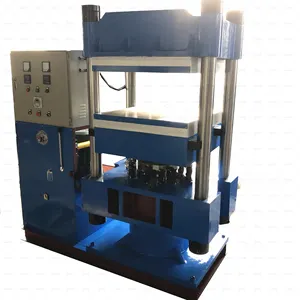

Understanding Tire Forming Machines

Tire forming machines are essential in the production of tires, serving as the backbone of modern rubber processing industries. These machines shape and mold the tire to its required specifications, ensuring durability and performance. Understanding the lifecycle of such machinery is crucial, as it determines the longevity and reliability of the equipment. A tire forming machine with an extended operational life can be a valuable asset, minimizing downtime and maintenance costs.

Types and Applications

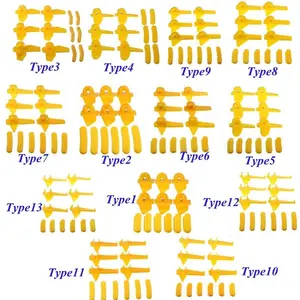

There are various types of tire forming machines, each designed to meet specific production needs. From simple manual presses to advanced automatic systems, the range is extensive. These machines are used in creating tires for various vehicles, including cars, trucks, and motorcycles, highlighting their versatility in the rubber processing sector. The application of the correct type of machine is pivotal in achieving the desired tire quality and performance.

Features and Materials

The features of a tire forming machine can significantly impact its functionality. Advanced models may include precision controls, energy-efficient designs, and enhanced safety features. The materials used in the construction of these machines, such as high-grade steel, contribute to their durability and performance. It is important to assess the features relative to the needs of your operation to ensure you select a machine that aligns with your production goals.

Advantages of Modern Machinery

Modern tire forming machines offer numerous advantages. They are designed to be more energy-efficient, reducing electricity consumption and operational costs. Additionally, the precision engineering involved in these machines ensures consistent tire quality, which is crucial for maintaining competitive advantage in the tire manufacturing industry. The integration of new technologies also allows for better monitoring and control of the tire forming process.

Space and Power Considerations

Before integrating a tire forming machine into your production line, consider the space it will occupy and the power it consumes. The ideal machine should fit within your allocated space while allowing room for operation and maintenance. Furthermore, power consumption is a critical factor, as it directly affects your utility expenses. Opting for a power-saving machine can lead to significant cost savings over time.

Selecting the Right Machine on Alibaba.com

Alibaba.com offers a diverse range of tire forming machines to cater to various production needs. When selecting the right machine, consider the operational space, power requirements, and the specific features that align with your production demands. With a variety of models available, Alibaba.com is a platform where you can connect with suppliers to find a machine that meets your requirements without the hassle of navigating through countless options alone.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4