Introduction

In the dynamic world of construction, innovative materials and techniques are constantly emerging, revolutionizing the way we approach building projects. One such game-changer is stucco mesh wire, a fundamental construction material known for its durability, cost-effectiveness, and ease of installation. This article delves into the understanding of stucco mesh wire, its benefits, and how to implement it in your building projects. We will also explore some successful case studies, demonstrating the transformative power of this versatile material.

Understanding Stucco Mesh Wire

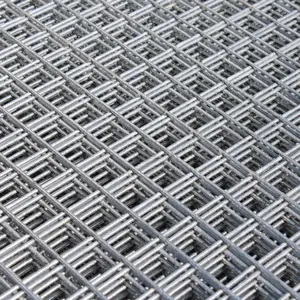

Stucco mesh wire, also known as stucco netting, is a fundamental construction material. It's primarily made of galvanized steel wire twisted into hexagonal meshes, providing support and reinforcement. Stucco netting is applied when installing stucco on a building's exterior, offering a stable surface for stucco application and preventing cracking by evenly distributing forces exerted on the wall. The selection of the right type of stucco netting, such as galvanized wire, fiberglass, or plastic, depends on the specific requirements of the wall construction.

Benefits of Using Stucco Mesh Wire in Building Projects

Stucco wire mesh or netting is a fundamental construction material that serves as a supporting and reinforcing mesh. It's primarily made of galvanized steel wire and twisted into hexagonal meshes. Stucco netting is installed over a building to provide a stable surface for stucco application, strengthening the stucco and preventing cracking by evenly distributing forces exerted on the wall surface. It's available in various types, including galvanized wire, fiberglass, and plastic, each suitable for different wall construction requirements.

Durability and Longevity

Stucco netting, a fundamental material in wall construction, is known for its durability and longevity. Made of galvanized steel wire and reverse twisted into hexagonal meshes, this structure provides a solid, uniform, and flat structure for high strength. Unlike other types of stucco netting, such as welded wire mesh or expanded metal mesh, the woven structure of stucco netting does not crack or loosen when cut into pieces, demonstrating its superior durability.

Cost-Effectiveness

Stucco siding, while considered one of the more expensive siding options, is a cost-effective choice in the long run. The average cost of stucco siding is around $8 per square foot as of 2023, with total costs ranging between $8,000 and $11,000. However, a well-installed stucco panel siding is a one-time investment, enduring more than 50 years with proper maintenance. The repair costs can vary, but with routine maintenance, costly repairs can be avoided. Thus, despite the initial investment, stucco siding proves to be a cost-effective solution due to its durability and low maintenance needs.

Ease of Installation

Installing stucco mesh wire is a straightforward process that can be easily mastered with a bit of practice. The first step involves measuring and precutting the wire to fit the walls. The wire is then held up to the wall, ensuring it rests on the bottom flange of the weep screed. The wire is then stapled along the wall, keeping the bottom edge straight. The process is repeated for additional rows of wire, ensuring a three-ring overlap for each new piece. Both outside and inside corners are handled by creasing and wrapping the wire, ensuring a tight fit.

Versatility and Aesthetic Appeal

Stucco has long been favored for its durability and versatility. Modern smooth stucco finishes offer a fresh take on this age-old material, providing a clean and sleek appearance. They can be customized with a diverse range of colors, allowing you to select a palette that complements your architectural design. Whether you’re aiming for a sleek monochromatic façade or incorporating contrasting colors and architectural details, smooth stucco serves as a versatile canvas for your design aspirations.

How to Implement Stucco Mesh Wire in Your Building Projects

Stucco netting, a crucial construction material, is available in two main types: self-furred and non-furred. Self-furred netting has ridges that provide spacing between the netting and the existing wall, allowing for proper ventilation and drainage. Non-furred netting requires additional furring strips to create the necessary gap. Regardless of the type you choose, it's essential to follow the manufacturer’s guidelines for correct installation. Both furred and non-furred stucco netting are ideal for various applications including Portland gypsum plaster, stucco one coat & 3 coat systems, masonry veneer, and ceramic tile.

Choosing the Right Stucco Mesh Wire

Choosing the right stucco netting for your project depends on various factors. Galvanized wire stucco netting is a popular choice as the zinc coating prevents rust, making it suitable for both interior and exterior applications. Other types include fiberglass and plastic stucco netting, each catering to different wall construction requirements. Stucco netting is also available as self-furred and non-furred. Self-furring netting allows for adequate bonding of materials, while non-furred netting requires additional furring strips to create a necessary gap between the netting and the substrate. Always follow the manufacturer’s guidelines for correct installation.

Installation Techniques

Installing stucco mesh wire involves several steps. Initially, pre-cut the wire and align it with the weep screed. Ensure the wire is tight before stapling. For subsequent runs, maintain an overlap where the wires meet. The corners require special attention, with the wire being wrapped around and stapled systematically. Inside corners are handled similarly, but the wire is bent the opposite way. For windows, you can either run the wire over and cut it out afterwards or stop right at them, having pre-measured and pre-cut the wire.

Maintenance and Care

Stucco repair and maintenance are crucial for the longevity of your building projects. It's important to avoid straight edges when patching, as they can make the repair more visible. Also, ensure that there's enough wire exposed from the existing stucco for the patch to tie into. If the wire is in poor condition, consider breaking out more stucco until you find good wire. Remember, the process of stucco repair is simple and requires minimal tools, but attention to detail can make a significant difference in the final result.

Case Studies: Successful Building Projects with Stucco Mesh Wire

One notable example of successful use of galvanized wire mesh, similar to stucco mesh wire, is the Sydney Opera House. The sails of the Opera House are made of 2194 pre-cast rib segments, some weighing up to 15 tons each. Galvanized mesh was exclusively used in the manufacture of these precast segments to provide long-term corrosion protection and to minimize the risk of cracking and rust staining of the gleaming white ceramic cladding tiles. After nearly 40 years exposure to salt spray and high humidity, the sail panels have shown no signs of deterioration.

Conclusion

Stucco mesh wire has proven to be a revolutionary material in the construction industry, offering unparalleled durability, cost-effectiveness, and versatility. Its ease of installation and aesthetic appeal make it a preferred choice for many builders. The right selection and proper installation of stucco mesh wire can significantly enhance the longevity and visual appeal of your building projects. The case of the Sydney Opera House stands as a testament to the enduring quality of this material. As we continue to innovate and evolve in the construction industry, stucco mesh wire is undoubtedly a tool that will remain relevant for years to come.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4