Spiral Welding Machine Overview

Spiral welding machines are specialized equipment designed for producing high-strength welded joints in a spiral pattern. These machines are integral to various industries, facilitating the construction of pipelines, structural projects, and other applications where long, continuous welds are necessary. The versatility of spiral welders allows for their use on a range of materials, including metals and certain non-metallic substances.

Types and Applications

The array of spiral welding machinery encompasses models suitable for different energy sources such as oil, gas, or electricity. These machines serve an essential role in sectors like chemical processing, mining, and construction. Depending on the specific industry requirements, spiral welders can handle diverse tasks, from creating intricate custom designs to reinforcing structural integrity in heavy-duty materials.

Features and Materials Compatibility

Spiral welding equipment is compatible with a variety of materials, from traditional metals to non-traditional ones like certain plastics or glass. The machines come with features that accommodate different welding techniques, including arc, braze, gas, resistance, and forge welding. This ensures that professionals can select a spiral welding system that aligns with their existing expertise and project demands.

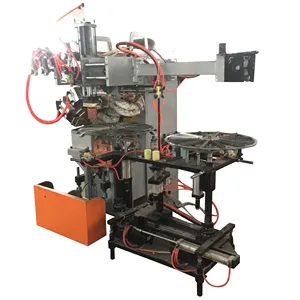

Machine Specifications and Technologies

When selecting a spiral welding machine, buyers can choose from compact, portable units to larger, automatic setups. Technological advancements have been integrated into these machines to enhance the welding process. Innovations such as digital interfaces and automatic feed systems contribute to the efficiency and precision of welding tasks, catering to the nuanced needs of various operations.

Operational Advantages

The operational benefits of using a spiral welding machine include the ability to maintain continuous production with minimal downtime. For environments where bright lights and sparks present challenges, certain models offer features like push-button operation and automatic welding capabilities, which can significantly improve the user experience and safety.

Choosing the Right Equipment

Selecting the appropriate spiral welder involves considering the size of the equipment, the material to be welded, and the preferred welding technique. Alibaba.com's collection caters to these diverse requirements, ensuring that clients can find a machine that meets their specific needs without the hassle of navigating through overly complex procurement processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4