Introduction to Sandblasting Equipment

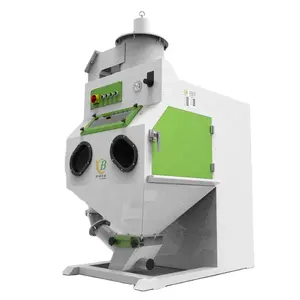

Sandblasting equipment, a vital category in surface preparation and finishing, encompasses a range of tools designed for cleaning, peeling, and etching various materials. This equipment uses abrasive materials propelled at high speeds to smooth out surfaces or remove contaminants. From portable sandblaster units to large-scale sand blasting machines, the variety available caters to both home hobbyists and industrial needs.

Types and Applications

The spectrum of sandblasting equipment includes portable bead blasters and mobile sandblasters, each serving distinct purposes. Portable options are ideal for small-scale projects and touch-ups, while their mobile counterparts are best suited for larger, on-site operations such as cleaning steel structures or tank bodies. The versatility of these tools allows for a wide range of applications, from delicate glass etching to robust metal surface preparation.

Features and Materials

A typical sand blaster comprises a blasting gun, an air compressor, and a blasting medium, often referred to as sand blaster media. The media can range from traditional sand to more specialized materials like glass beads or walnut shells. Each medium is chosen based on the desired finish and material compatibility. Features such as adjustable pressure settings and ergonomic designs enhance the functionality and user experience of the equipment.

Advantages of Modern Sandblasters

Modern sandblasting equipment, like the wet sand blaster and pressure washer sandblaster, offers improved efficiency and reduced dust generation. These advancements not only improve the blasting process but also contribute to a safer working environment. The adaptability of equipment to various media types, such as abrasive blaster media and glass bead blaster options, provides users with the flexibility to tackle different tasks with a single machine.

Choosing the Right Equipment

Selecting the appropriate sandblasting equipment is crucial for achieving desired results. Factors to consider include the size of the project, the type of surface being treated, and the specific finish required. Whether it's a grit blaster for aggressive surface removal or a mobile sandblaster near me for convenient on-site work, the right tool can significantly impact the efficiency and quality of the job.

Maintaining Your Sandblasting Equipment

Maintenance is key to prolonging the life and performance of any sandblasting equipment. Regular checks and cleaning of the blasting gun, hose, and nozzles are essential. Proper storage of portable abrasive blasters and media will ensure that the equipment is ready for use when needed, providing reliable service for various blasting projects.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4