Introduction to Safety Shoe Production Lines

The safety shoe production line is an assembly of specialized machinery designed to manufacture protective footwear. This category encompasses a variety of machines, each serving a specific function in the creation of safety shoes, which are essential in industries where foot protection is paramount. From automated equipment to precision hand tools, these production lines are integral to the fabrication of durable and reliable safety footwear.

Types of Machinery in Production Lines

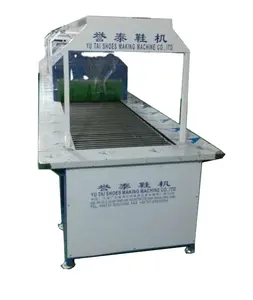

A comprehensive safety shoe production line includes several types of machinery. Cutting presses and clicker cutter machines are employed for shaping materials with precision, while embroidery machines add detailed stitching and logos. Advanced lines may also feature steamers for softening materials, pressers, and machines for applying footwear primer, cement, and for pressing outsoles. Each machine plays a crucial role in the multi-step process of safety shoe manufacturing.

Applications and Features

The application of a safety shoe production line extends across various stages of shoe making. These lines are designed to handle the robust materials used in safety shoes, such as heavy-duty leathers and synthetic composites. Features of these machines often include high durability, efficiency in production, and the ability to handle complex tasks with precision. The versatility of a production line allows for the creation of footwear that meets diverse safety standards and design specifications.

Materials and Advantages

Materials processed on a safety shoe production line range from leather to synthetic fabrics, all selected for their protective qualities. The advantages of using a dedicated production line include consistency in product quality, increased production speed, and the ability to meet bulk order demands. These lines are engineered to optimize the manufacturing process, ensuring that each pair of safety shoes meets the industry requirements for protection and longevity.

Considerations for Setup

When integrating a safety shoe production line into a workshop, space considerations are crucial. Machinery size varies, and it's important to maintain an efficient workflow. Prospective buyers should assess their workspace dimensions to ensure a proper fit for the machinery, allowing for a seamless operation within their production environment.

Choosing the Right Production Line

Selecting the appropriate safety shoe production line requires careful consideration of the specific needs of a shoe making business. Alibaba.com's platform facilitates this selection by offering a diverse range of options. Utilizing the filter functions can aid in narrowing down the choices based on machine size, function, and other defining features, ensuring a well-suited production line for any safety shoe manufacturer's requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4