Introduction to Polyester Fabric Bag Filters

Polyester fabric bag filters stand as a cornerstone in industrial filtration, offering a versatile solution to maintain clean and safe work environments. These filters are crafted to trap and manage a spectrum of fine particulates, including sawdust, sand, and dust, which are by-products of various manufacturing processes. The efficiency of polyester fabric bag filters in capturing such particles is crucial for not only safeguarding health but also for ensuring a clean and orderly workspace.

Types and Applications

The application of polyester fabric bag filters spans across numerous industries, each with its unique demands. From woodworking to cement production, these filters are integral in controlling emissions and managing waste. The types of filters vary, with options like singed polyester felt filter bags, which offer enhanced dust release properties due to their singed finish. Selecting the appropriate filter type is essential for optimal performance in specific industrial applications.

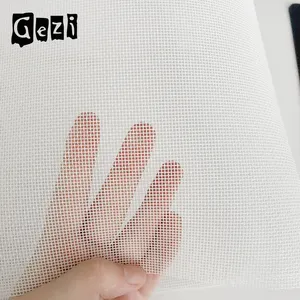

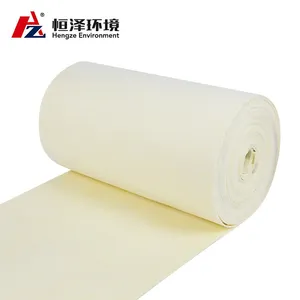

Features and Materials

Polyester fabric bag filters are distinguished by their material properties, which include resistance to abrasion and a high tolerance to a variety of chemicals. The construction of these filters often involves advanced techniques to enhance their durability and filtration capacity. Materials such as singed polyester felt not only improve the filter's lifespan but also its efficiency in particle retention.

Advantages of Polyester Fabric Bag Filters

The advantages of utilizing polyester fabric bag filters in industrial settings are manifold. Their design ensures a high dust holding capacity, which translates to less frequent changes and maintenance. The inherent strength of polyester also means these filters can withstand continuous use and harsh conditions without compromising their integrity. Moreover, the adaptability of polyester fabric bag filters to various temperatures and environments makes them a reliable choice for diverse operational needs.

Considerations for Selection

When integrating polyester fabric bag filters into your operations, it is imperative to match the filter to the specific appliance. Compatibility with existing systems ensures efficiency and prevents operational disruptions. It is recommended to consult equipment manuals to ascertain the correct filter specifications. Maintaining an adequate inventory of polyester fabric bag filter packs is also advisable to ensure continuity in operations and to address any immediate replacement needs.

Conclusion

In conclusion, the selection of the right polyester fabric bag filter is a critical decision for any industry reliant on clean air and workspaces. With a variety of types like singed polyester felt filter bags available, businesses can find the specific filtration solution that meets their operational requirements. Ensuring a clean and safe working environment is not just a regulatory compliance matter but also a commitment to the well-being of the workforce and the efficiency of production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4