Introduction to Plate Threading Machines

Plate threading machines are essential tools in the field of manufacturing, designed to create precise threads on bolts, screws, and other fasteners. These machines utilize die plates to carve threads into workpieces, a process critical for producing components with the necessary grip and tension for construction and machinery assembly.

Types and Applications

There are various models of plate threading machines, each suited to different threading tasks. From creating unique nail shapes to specialized fasteners, these machines serve a broad range of applications. They are indispensable in industries such as automotive, construction, and metalworking, where the production of threaded parts is a daily requirement.

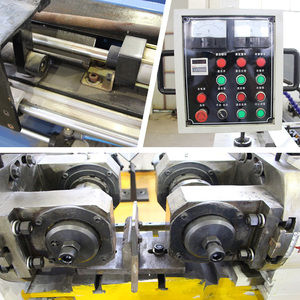

Operational Features

The operational capacity of a thread rolling machine is characterized by its integration of variable speeds, allowing for flexibility in production rates. With the capability to accommodate different die sizes, these machines can adapt to various production needs. The integration of advanced motors enhances the efficiency of the threading process, ensuring consistent output without the excessive noise that can disrupt a work environment.

Technical Specifications

A typical thread rolling machine operates on an average voltage of 380V and a frequency of 50Hz, with a production capacity that can cater to diverse manufacturing demands. The robust construction of these machines, including wear-resistant motors and a power distribution box, contributes to their durability and reliability in high-frequency quenching processes.

Advantages of Automated Systems

The evolution of automatic thread rolling machines has brought about a significant increase in efficiency. These systems, available in both semi-automatic and fully automatic configurations, offer precision and ease of use with electro-hydraulic execution functions. The impact-resistant and anti-vibration features of these machines underscore their durability, while their self-suction and anti-fouling capabilities ensure a clean operation.

Choosing the Right Machine

Selecting the appropriate plate threading machine from the array of options available on Alibaba.com can be a streamlined process. Prospective buyers can find machines compatible with nearly all types of special molds, capable of producing a wide array of threaded components. The low noise operation and robust design make these machines a valuable addition to any production line.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4