Exploring Perforated Protective Film

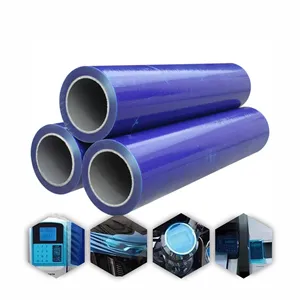

Perforated protective film is a versatile product designed to safeguard surfaces and materials across various applications. This film is punctured with small holes, providing a balance between protection and breathability, making it ideal for a multitude of uses.

Types and Applications

Diverse in its utility, perforated protective film caters to a range of needs. From UV-resistant options that protect delicate plants in harsh sunlight to blackout films for light-sensitive environments, the applications are extensive. This film is also essential in everyday scenarios, such as preserving food freshness with food-grade PVC film or safeguarding furniture during a move.

Material Insights

The materials used in perforated protective film include PE (Polyethylene) and PVC (Polyvinyl Chloride), among others. These materials are chosen for their durability and flexibility. While transparent films are prevalent, colored options are available to suit specific requirements without compromising the visibility of the protected items.

Environmental Considerations

For those seeking eco-friendly solutions, biodegradable options within the perforated protective film category offer an environmentally conscious choice without sacrificing performance. These films decompose over time, reducing environmental impact.

Features and Advantages

The features of perforated protective film include its adaptability to different temperatures and resistance to various environmental factors. The perforation allows the material to breathe, preventing condensation and promoting a longer lifespan of the underlying product. Its ease of use and removal adds to its practicality, making it a preferred choice in many industries.

Choosing the Right Film

Selecting the appropriate perforated protective film depends on the specific requirements of the task at hand. Factors such as the degree of UV protection, the size of the perforations, and the material's biodegradability play a crucial role in determining the right film for the job.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4