Introduction to Paint Production Machinery

The realm of industrial paint manufacturing is a complex and intricate one, necessitating specialized paint production machinery to meet the demands of this bustling sector. These machines are pivotal in the process of creating various types of paints and coatings, which are essential in numerous industries ranging from automotive to construction. The machinery's role is to blend, mix, and refine raw materials to achieve the desired consistency, color, and performance characteristics of the end product.

Types and Applications

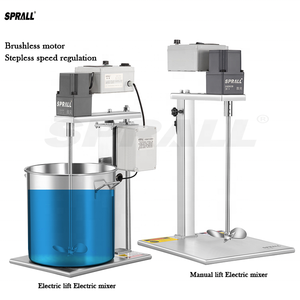

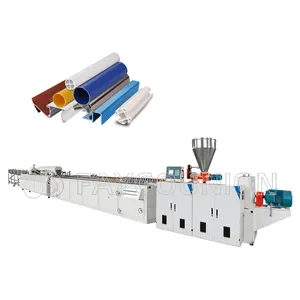

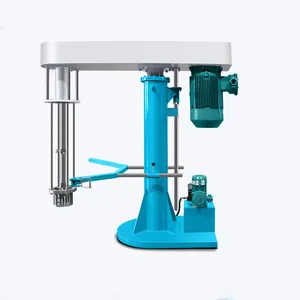

There exists a diverse array of machinery tailored for paint production, each serving a unique function within the manufacturing process. This includes dispersers for mixing, mills for particle size reduction, and mixers for combining raw materials uniformly. The applications of these machines are just as varied, catering to the production of water-based emulsions, solvent-based solutions, and even powder coatings, each requiring a specific type of machine to produce.

Features and Materials

The features of paint mixing equipment are designed to ensure efficiency and quality in paint production. These machines often boast robust construction with materials like stainless steel to withstand the corrosive nature of paint constituents. Advanced models may include features such as vacuum and heating capabilities to facilitate certain chemical reactions and drying processes within the paint manufacturing cycle.

Advantages of Modern Machinery

Modern paint manufacturing equipment brings forth a multitude of advantages. Enhanced precision in the mixing and grinding processes ensures uniformity in product quality, while automation features reduce the need for manual intervention, thus optimizing production times and reducing labor costs. Additionally, the integration of digital controls allows for more accurate monitoring and adjustments during the production process.

Environmental Considerations

In an era where environmental sustainability is paramount, contemporary paint production systems are designed with eco-friendliness in mind. These systems aim to minimize waste and reduce the environmental impact of paint production by improving raw material usage efficiency and incorporating recycling processes wherever possible.

Choosing the Right Machinery

Selecting the appropriate paint processing equipment is crucial for any business in the industry. Factors such as production capacity, the viscosity of materials to be handled, and the specific type of paint to be produced are critical considerations. Alibaba.com serves as a gateway for businesses to connect with a vast array of suppliers offering machinery that caters to these diverse needs, without endorsing any particular brand or making absolute claims about the products.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4