Introduction to Manual Cutting Tables

A manual cutting table is a fundamental piece of equipment in the realm of material processing, particularly for woodworking and metalworking. This type of table is designed to facilitate the precise and efficient cutting of various materials, offering a stable platform and the ability to accommodate different manual saw types.

Types and Applications

There are several types of manual cutting tables available, each suited to specific tasks and materials. From simple straight cuts to complex angles, these tables can be adjusted to meet the demands of the project at hand. Their applications span across industries, serving as an indispensable tool in workshops, construction sites, and manufacturing facilities where manual control over cutting is preferred or necessary.

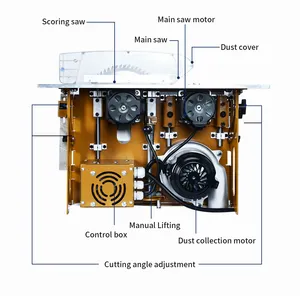

Features and Materials

The construction of a manual cutting table often involves robust materials such as steel or aluminum, ensuring durability and stability. Features may include adjustable components, measurement guides, and clamps to secure the material in place. The design aims to support accurate manual operations while minimizing the physical strain on the user.

Advantages of Manual Cutting

Opting for a manual cutting table brings several advantages, including the ability to work without electricity, which can be crucial in remote locations. It also allows for a hands-on approach, which many craftsmen prefer for greater control over the cutting process. Additionally, these tables can be more cost-effective and easier to maintain than their powered counterparts.

Considerations for Selection

When selecting a manual cutting table, it's important to consider the size, material compatibility, and the type of manual saws it can accommodate. Prospective buyers should assess the table's adaptability to different projects and its ease of use to ensure it meets their specific needs.

Finding the Right Manual Cutting Table on Alibaba.com

Alibaba.com offers a diverse array of manual cutting tables to suit various operational requirements. Whether for intricate woodworking tasks or robust metal cutting, the platform connects buyers with a multitude of suppliers to find a table that aligns with their material processing needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4