A low pressure compressor is a type of compressor that is designed to operate at a lower discharge pressure, typically below 150 psi. These compressors are essential in various industrial applications where high volume and low pressure are required. The low pressure air compressor is commonly used in industries such as manufacturing, construction, and agriculture, where they power a wide range of tools and machinery.

Types and Characteristics of Low Pressure Compressors

The market offers a variety of low pressure compressors, each designed to meet specific operational needs. The low pressure screw compressor stands out for its ability to provide a consistent air flow, ideal for operations that require a continuous air supply. For environments where air quality is paramount, the low pressure breathing air compressor is engineered to deliver the purest air possible. In contrast, the high volume low pressure compressor is tailored for applications needing large volumes of air at lower pressures, such as in textile manufacturing or food processing industries. Specialty compressors like the ingersoll rand low unload sump pressure model are designed for energy efficiency, automatically adjusting the air supply to match the demand, thus reducing operational costs.

Structure and Operation of Low Pressure Compressors

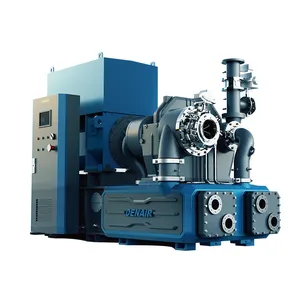

The structure of a low pressure compressor is a complex assembly of components working in unison. The engine or motor is the driving force, providing the necessary power to the compressor unit. The gearbox, a critical component, manages the transfer of this power to the compressor's screws or pistons. In screw compressors, air is drawn into the compression chamber and captured between two meshing screws that compress the air as they rotate. The compressed air then moves to a pressure vessel, where it is stored until needed. The PLC (Programmable Logic Controller) oversees the operation, adjusting parameters such as pressure and flow rate to ensure the system operates within the desired limits. This intricate structure is designed for durability and efficiency, ensuring that the compressor can handle the demands of industrial use.

Materials and Their Properties

Compressors are built with materials selected for their strength, durability, and suitability for the task. Bearings, for instance, are often made of hardened steel or specialized alloys that can withstand the high-speed rotations and loads they are subjected to. Gearboxes are constructed from robust metals capable of handling the torque and stress of operation. The choice of stainless steel or aluminum for pressure vessels is dictated by the need for a lightweight yet strong container that can hold compressed air without leakage. These materials are also chosen for their resistance to corrosion, which is crucial in preventing contamination of the compressed air and ensuring the longevity of the compressor.

Business Usages and Industrial Applications

Low pressure air compressors are integral to a wide array of business operations. In the manufacturing sector, they are essential for running pneumatic machinery and automation systems, which are the backbones of mass production. The construction industry relies on them to power pneumatic tools that are more reliable and powerful than their electric counterparts. In agriculture, they are used in automated feeding systems and crop spraying equipment. The value these compressors bring to businesses lies not only in their functionality but also in their ability to improve productivity and efficiency, leading to reduced operational costs and increased profitability.

Functions and Tasks

The low pressure compressor is designed to fulfill a range of functions across various industries. It can power air tools, operate pneumatic controls, and even be used in HVAC systems for climate control. The versatility of these compressors allows them to be adapted for specialized tasks, such as providing the air supply for aeration in wastewater treatment plants or supplying the necessary pressure for spray painting equipment in the automotive industry.

Features and Unique Selling Points

Distinctive features of low pressure compressors include their operational efficiency and the ability to provide a stable air supply at lower pressures, which is gentler on tools and machinery, leading to less wear and tear. Some models boast innovative designs like the kaeser low pressure compressor, which may include advanced sound-dampening enclosures to reduce noise pollution in sensitive environments. The unique selling points of these compressors often revolve around their reliability, energy efficiency, and the advanced technology that allows for easy integration into existing systems.

Benefits and Positive Outcomes

The use of a low pressure compressor brings numerous benefits to an industrial setting. They are energy-efficient, reducing electricity costs for businesses. Their lower operating pressures result in less strain on the compressed air system and the tools it powers, which translates to lower maintenance costs and downtime. Additionally, the improved air quality provided by certain models ensures that sensitive operations, such as food production or pharmaceutical manufacturing, are not compromised by contaminants.

How to Choose the Right Low Pressure Compressor?

Selecting the appropriate low pressure compressor for your business involves understanding your air requirements. Evaluate the volume of air needed, the pressure requirements of your tools, and the operating conditions. For example, a low pressure gas compressor would be suitable for applications that involve gas transfer, while a low pressure screw compressor might be the best fit for continuous operation. Consider the compressor's cooling method, lubrication style, and noise level to ensure it aligns with your operational environment. After-sales service options are also critical; look for manufacturers that provide comprehensive technical support and maintenance services.

How to Maintain Your Low Pressure Compressor?

Proper maintenance is key to the longevity and performance of your low pressure compressor. Routine checks should include inspecting air filters, oil levels, and belts for wear and tear. Following the manufacturer's recommended service intervals is crucial, especially for complex systems like those from Ingersoll Rand or Kaeser, which may require professional servicing to maintain optimal performance. Regular maintenance not only extends the life of the compressor but also ensures it operates at peak efficiency, saving energy and costs over time.

What Are the Considerations for Installation?

Installing a low pressure compressor requires careful planning. The site should be spacious enough for the unit and allow for adequate maintenance access. Proper ventilation is essential to prevent overheating, and a stable power supply is needed to avoid electrical issues. Consideration of the noise level is also important; if the compressor is to be installed in a noise-sensitive area, look for models with low noise output or those with sound-dampening features.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4