What are High-quality Laboratory Filter Press

High-quality laboratory filter presses are sophisticated equipment designed for separating solids from liquids in a wide range of applications. They are essential tools in various industries such as pharmaceuticals, food and beverage, mining, and waste treatment. The primary purpose of a laboratory filter press is to remove a particular substance from a mixture by using pressure and a filter medium, typically a series of specialized filter papers or cloths. These devices are invaluable for conducting precise and controlled filtration processes in a laboratory setting where the accuracy of results is paramount.

The operation of a laboratory filter press is based on the principle of applying pressure to the mixture using a filter medium. The mixture is fed into the press, and then a combination of air or hydraulic pressure is used to force the liquid through the filter medium, leaving the solid particles behind. The efficiency of this process is highly dependent on the quality of the filter medium and the design of the press itself. Manufacturers consider factors such as material composition, pore size, and thickness when producing the filter medium to ensure optimal filtration.

High-quality laboratory filter presses are designed with various features to enhance usability and reliability. They often come with user-friendly interfaces that allow for easy operation and monitoring. Additionally, many models have automatic features such as plate shifting, cake washing systems, and pre-coating for more efficient filtration. These presses are engineered to handle small sample volumes, making them ideal for testing and research purposes where large-scale equipment is not necessary.

Types of High-Quality Laboratory Filter Press

The selection of a laboratory filter press depends on various factors such as the type of slurry being processed, the desired clarity of the final filtrate, and the scale of operations. Here are some common types:

-

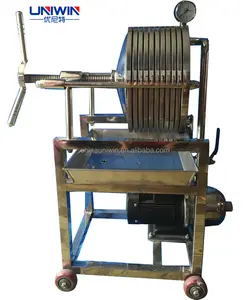

Plate and Frame Filter Press: This is the most common type of laboratory filter press used for separating solids from liquids. It consists of a series of plates with filter media between them that is pressed together under hydraulic force. The spaces between the plates are filled with the suspension, and as the filter press cycles, it collects the separated solids.

-

Membrane Filter Press: A more specialized variant, membrane filter presses use membranes to filter the sample. They are particularly useful for ultrafiltration applications where fine particles need to be separated from the liquid. This type is not as widely used due to its higher cost but is essential for precision separation tasks.

-

Recessed Plate and Frame Filter Press: This design incorporates a series of plates and frames with filter cloth between them. The slurry is pumped into the press, and the filtrate flows through the cloth into a collection reservoir. It's suitable for both academic research and industrial applications.

-

Automatic Filter Press: Equipped with mechanisms that allow for the continuous operation without manual intervention, automatic filter presses are ideal for larger-scale operations requiring consistent and efficient separation of solids and liquids.

-

Filter Press with Gasketed Plates: These have an additional gasket material around the edge of each plate which prevents leakage during filtration. They are used in processes where a high degree of containment is necessary.

How to choose High-quality Laboratory Filter Press

Selecting the right laboratory filter press for your business involves understanding your specific needs in terms of capacity, material quality, application type, and operational preferences. Consider the volume of material that needs to be processed; this will help determine the size of the filter press required. Capacity is typically expressed in liters of material but can also be denoted in other units like cubic feet or gallons.

Material quality is crucial when dealing with sensitive samples or when durability is a concern. The core components such as motors, PLCs (Programmable Logic Controllers), and gears must be of high quality for reliable operation. Additionally, consider whether you need specialized membranes for your filtration process.

Application type—whether it's for food testing, chemical analysis, or wastewater treatment—will guide you in selecting the appropriate filter press. Each type offers unique advantages suited for different industries.

Finally, operational considerations such as manual or semi-automatic grade should align with your laboratory's workflow and staff expertise. A more advanced system might provide greater efficiency but also require more specialized training.

About High-quality Laboratory Filter Press on Alibaba.com

Alibaba.com stands as a global marketplace connecting businesses with a vast selection of laboratory filter presses suitable for every filtration need. From robust stainless steel models that can withstand extensive use to sophisticated automatic systems equipped with cutting-edge technology, Alibaba.com caters to diverse industrial requirements with an emphasis on quality and efficiency.

The platform's extensive network of suppliers ensures access to a wide range of filter press types while offering flexibility in machinery size and configuration. Whether a business needs a compact benchtop unit for occasional use or a large-capacity industrial-grade filter press for continuous operation, Alibaba.com simplifies the procurement process with detailed product descriptions and supplier profiles.

Moreover, Alibaba.com prioritizes secure transactions through its Trade Assurance service, providing protection from order placement through delivery completion. This commitment to facilitating reliable trade experiences underlines why many consider Alibaba.com an indispensable resource when it comes to finding high-quality laboratory filter presses that meet both technical demands and commercial objectives.

Common FAQs for High-quality Laboratory Filter Press

What is a laboratory filter press used for?

A laboratory filter press is a device used to separate solids from a liquid to create a clarified liquid (filtrate) and a solid (retentate), commonly used in industries such as pharmaceuticals and food processing for quality assurance.

How does a laboratory filter press work?

A laboratory filter press works by applying mechanical pressure to a liquid-solid mixture to force the liquid through a filter medium (cloth or mesh) that retains the solids, while allowing the clarified liquid (filtrate) to pass through.

What are the key components of a laboratory filter press?

Key components of a laboratory filter press typically include a pump for creating pressure, a chamber for holding the solid and liquid phases (filter plates or frames), and a means of collecting the filtrate (usually via gravity through a drain or by vacuum).

What types of laboratory filter presses are available?

There are several types of laboratory filter presses available including manual, semi-automatic, and automatic high-pressure presses, each with specific applications and levels of automation suited to various laboratory needs.

How do I choose the right laboratory filter press for my business?

Selecting the right laboratory filter press depends on your specific application, required pressure rating, material compatibility, automation needs, and after-sales service considerations. Compatibility with your existing system and operational preferences are crucial.

Can laboratory filter presses be customized to fit specific requirements?

Yes, many suppliers offer customization options for laboratory filter presses to meet particular operational or system integration requirements. It is recommended to discuss these needs directly with suppliers to ensure compatibility and optimal functionality.

What materials are laboratory filter presses made from?

Laboratory filter presses are typically made from materials like stainless steel which is durable and resistant to chemicals, or plastic such as polypropylene which is lightweight and resistant to corrosion.

Are there any industry-specific considerations when choosing a laboratory filter press?

Yes, industry-specific considerations include the compatibility of the filter material with the liquid being filtered, the required pressure rating, and any industry-specific certifications or standards that need to be met.

How do I ensure that the laboratory filter press I choose is easy to clean and maintain?

Look for features such as removable filter plates and easy-to-clean surfaces when choosing a filter press. Stainless steel and certain plastics like polypropylene are often preferred for their hygienic properties and ease of maintenance.

What after-sales services should I consider when purchasing a high-quality laboratory filter press?

Consider after-sales services such as online support and video technical support, field maintenance and repair services, and engineers available to service machinery overseas. These services can be valuable in ensuring ongoing support and optimal equipment performance.

Is it possible to find high-quality laboratory filter presses on Alibaba.com?

Yes, Alibaba.com hosts a marketplace where various suppliers offer high-quality laboratory filter presses that can be filtered according to desired features like material compatibility, after-sales services provided, and whether automatic operation is an option.

How do I ascertain that a supplier's product specifications meet my requirements?

Reviewing detailed product specifications provided by suppliers on Alibaba.com or contacting them directly to inquire about customization options can help ascertain whether their products meet your specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4