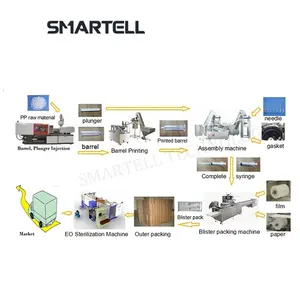

Introduction to Injection Needle Making Machines

Injection needle making machines are specialized devices designed to manufacture high-precision medical needles through the process of plastic injection molding. These machines are integral to the production lines of medical equipment manufacturers, catering to a critical component in healthcare delivery.

Types and Applications

The variety of injection needle making machines encompasses models that cater to different scales of production and design complexities. These machines are adept at producing needles for various medical applications, ranging from simple hypodermic needles to more complex biopsy needles, ensuring they meet the stringent standards of the medical industry.

Technical Features and Materials

Advanced injection needle making machines are equipped with specialized screws that enhance plasticizing capabilities, ensuring efficient shot weights and speeds. The construction of these machines often involves robust materials that contribute to the durability and longevity of the equipment. The clamping units, often made with steel bushings, are designed to minimize wear resistance and lubrication needs, leading to cost savings in maintenance.

Machine Advantages and Precision

The precision of an injection needle making machine is paramount, as it dictates the quality and safety of the needles produced. These machines offer improved accuracy, which is crucial for medical applications. The clamping force of these machines is adjustable, ensuring that the exact force required for specific needle designs is applied, thus preventing material wastage and ensuring consistent product quality.

Capacity and Durability

With clamping forces ranging from 2,000 kN to 13,000 kN, injection needle making machines are capable of withstanding significant machining forces, which is essential for mass production without compromising the integrity of the needles. The durability of these machines is a testament to their ability to operate continuously in a demanding production environment.

Environmental and Economic Efficiency

Modern injection needle making machines are designed with an eye on environmental and economic efficiency. The reduction in lubricant usage not only decreases the operational costs but also lessens the environmental impact. Additionally, the ability to use plastic granules effectively shapes them into precise dimensions, which is a step forward in sustainable manufacturing practices.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4