An industrial kettle is a specialized device designed to meet the rigorous demands of large-scale food and beverage production. These kettles are integral to operations in various industries, providing a reliable means of cooking, heating, and processing a wide range of products.

Types and Characteristics of Industrial Kettles

There are several types of industrial kettles, each with unique characteristics that cater to different processing needs. The industrial steam kettle, for example, is known for its efficient heat transfer and rapid heating capabilities, making it ideal for quick cooking processes. On the other hand, industrial electric kettles offer precise temperature control, which is crucial for processes that require steady and consistent heat. Industrial gas kettles are often favored for their lower operating costs and high heat output, suitable for operations where steam or electricity is not readily available or cost-effective. The industrial soup kettle is designed with a more gentle heating mechanism to preserve the quality and consistency of liquid-based foods.

Structure and Operation of Industrial Kettles

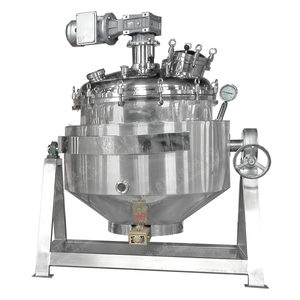

The structure of an industrial kettle is a testament to engineering designed for durability and functionality. The core components include a large cooking pot, often made of stainless steel, and a heating element that can be a steam jacket, an electric coil, or a gas burner. The steam jacketed models circulate steam within a double-walled kettle to heat the contents evenly without direct contact with the flame, reducing the risk of scorching. Electric models use immersed elements or surface contact to transfer heat, while gas kettles typically have burners underneath. Many kettles come equipped with an integrated agitator, which is motor-driven and can perform various motions, from simple stirring to complex scraping actions, to ensure even cooking and prevent sticking.

Materials and Their Properties

The choice of material for an industrial kettle is critical. Most are constructed from stainless steel, particularly 304 stainless steel, due to its resistance to corrosion and its non-reactive properties, which are essential when dealing with acidic or alkaline foods. This material also withstands the rigors of daily use and frequent cleaning without degrading, ensuring a long service life and maintaining food safety standards.

Business Usages and Applications

Industrial kettles are pivotal in settings such as beverage factories, snack food production, and meat processing plants. They are instrumental in the mass production of jams, sauces, chocolates, and candies in the snack industry, where consistency and quality are paramount. In meat processing, these kettles are used for cooking large batches of meat with precise temperature control, which is essential for both safety and quality. The industrial cooking kettle also finds its place in the preparation of stews and soups in large-scale catering and restaurants, demonstrating its versatility and value in various culinary operations.

Functions and Tasks

An industrial kettle is designed to perform a multitude of tasks. It can cook, mix, simmer, and boil various types of food products. With the addition of specialized attachments, such as steam baskets or mixing arms, the functionality of these kettles can be further expanded to include steaming and more complex mixing tasks, making them indispensable in the food processing industry.

Features and Unique Selling Points

The distinct features of an industrial kettle include its robust construction, high-capacity cooking potential, and advanced safety features like automatic shut-off and boil-dry protection. The industrial steam jacketed kettle stands out for its ability to provide uniform heating, which is a unique selling point for businesses that prioritize food quality and consistency.

Benefits and Positive Outcomes

The benefits of using an industrial kettle in a commercial setting are manifold. These kettles offer a high degree of control over the cooking process, which can lead to improved product quality and consistency. The efficiency of these kettles can also lead to cost savings through reduced energy usage and labor costs, as they can often replace several pieces of smaller equipment.

How to Use and Operate Effectively

Operating an industrial kettle effectively requires understanding its functions and features. For instance, when using a steam jacketed kettle, it's important to monitor steam pressure to maintain consistent heat. With electric kettles, temperature settings should be adjusted according to the specific cooking task. Regular stirring or agitation, if not automated, is crucial to prevent burning and sticking.

How to Choose the Right Industrial Kettle

Selecting the right industrial kettle involves assessing the volume of food to be processed, the type of food, and the specific cooking methods required. For high-volume liquid processing, a steam jacketed kettle with an agitator might be the best choice. For operations requiring precise temperature control, an electric kettle would be more suitable.

How to Clean and Maintain

Cleaning an industrial kettle typically involves draining the contents, rinsing with water, and then cleaning with a food-grade detergent. Scrubbing should be done with non-abrasive tools to avoid damaging the stainless steel surface. Regular maintenance includes inspecting the agitator and heating elements for wear and ensuring that all safety features are functioning correctly.

How to Install

Installation of an industrial kettle should always be performed by qualified technicians. It involves setting up the kettle in the designated area, connecting it to the power and heat source, and ensuring all components are properly assembled. For steam kettles, this also means connecting to the steam source and ensuring that the steam lines are properly insulated.

What are the core components of an industrial kettle?

The core components of an industrial kettle include the motor, which powers the agitator, the heating element—whether it's a gas burner, electric element, or steam jacket—and the PLC (Programmable Logic Controller) for automated operations. High-quality bearings and gears are also integral to the smooth operation of the kettle's moving parts.

What after-sales services are provided for industrial kettles?

After-sales services for industrial kettles typically include online support, video technical support, and field maintenance. Additionally, many manufacturers offer engineers available to service machinery overseas, ensuring that any issues can be promptly and effectively resolved.

What should be considered when purchasing an industrial kettle on Alibaba.com?

When purchasing an industrial kettle on Alibaba.com, consider the kettle's capacity, material, specific features like agitators and safety functions, and the type of heating it utilizes. It's also important to review the machinery test report, the marketing type, and the after-sales services provided. Alibaba.com lists various suppliers, offering a broad selection to meet the needs of different businesses.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4