Introduction to Hydraulic Beam Bending Machines

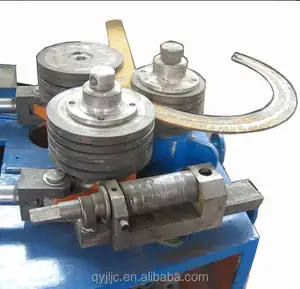

Hydraulic beam bending machines are integral components in metal fabrication, offering a blend of speed and precision for bending operations. These machines leverage hydraulic pressure to manipulate metal beams into various angles and shapes, catering to a wide array of industrial applications.

Features and Applications

The versatility of a hydraulic beam bending machine lies in its ability to handle different materials and thicknesses, making it suitable for a range of industrial tasks. From construction to automotive industries, these machines are pivotal in shaping metal sheets for specific uses. The inclusion of hemming capabilities further enhances their utility by allowing the folding of metal edges, which is crucial for safety and manufacturing aesthetics.

Advantages of Hydraulic Beam Bending Technology

Opting for a hydraulic beam bending machine brings several advantages to the production floor. Notably, the reduction of metal wastage is a significant benefit, as the machine's precision ensures optimal use of materials. The hydraulic mechanism also contributes to a faster production rate, which can be a critical factor in meeting project deadlines and increasing throughput.

Considerations for Selection

When selecting a hydraulic beam bending machine, several factors must be considered to ensure it meets your operational needs. Tonnage, or bending force, is crucial for determining the machine's capability to shape metal. Additionally, the bending length must align with the size of the materials being worked on. The physical dimensions of the machine are equally important, as it must fit within the designated workspace without necessitating extensive rearrangements.

Choosing the Right Machine on Alibaba.com

For businesses seeking a reliable hydraulic beam bending machine, Alibaba.com presents a comprehensive collection to suit various preferences. The platform's assortment includes machines with diverse specifications, allowing buyers to find the right match for their operational requirements without the constraints of a single brand or manufacturer.

Final Thoughts

In conclusion, a hydraulic beam bending machine is a substantial investment for any metalworking operation, promising efficiency and adaptability. While exploring options on Alibaba.com, buyers can compare different models to find a machine that aligns with their material handling needs and workspace dimensions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4