A glue spray is a multipurpose bonding agent that emits a fine mist of adhesive via an aerosol delivery system, suitable for a myriad of tasks. Renowned for its ease of use, swift application, and robust bond strength, the glue spray adhesive is indispensable in sectors that demand rapid and uniform glue distribution, adhering to a plethora of materials such as textiles, timber, metals, and synthetics.

Types and Composition of Glue Spray

The aerosol glue spray segment encompasses a diverse array of formulations, each engineered for specific substrates and applications. Whether it's a textile glue spray crafted for fabric projects or bespoke mixtures for carpentry and transport, the principal ingredient is typically synthetic rubber or pure silicone, guaranteeing a tenacious and lasting linkage. The 3m adhesive spray glue stands out for its superior industrial caliber and dependability. Variants like the mod podge spray are celebrated for their craft-friendly attributes, while the 3m spray on glue earns accolades in the automotive realm for its exceptional thermal tolerance and enduring adhesive strength.

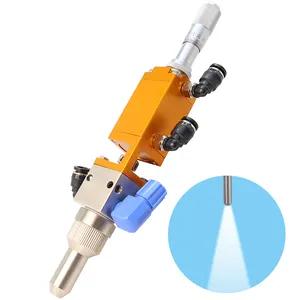

Structure and Operation of Glue Spray

The anatomy of a glue spray comprises a pressurized container, a valve, and an actuator or nozzle. Encased within is the adhesive compound alongside a propellant under pressure. Depressing the actuator opens the valve, propelling the adhesive out as a fine spray. This mechanism affords meticulous command over the volume and spread of the glue, essential for tasks demanding a consistent layer, such as applying cloth glue spray to automotive headliners or material glue spray for furnishing fabrics.

Materials and Properties in Glue Spray

The constituents of glue spray products are selected for their bonding prowess and affinity with various surfaces. Synthetic rubber imparts elasticity and resilience, while silicone offers unmatched thermal stability and pliability. These materials ensure that offerings like glue with spray yield connections that are robust yet flexible, and resistant to fluctuations in temperature and moisture, a critical feature for outdoor or industrial environments.

Business Usages and Applications of Glue Spray

Glue spray adhesives are essential across commercial landscapes. In manufacturing, glue spray for fabric is employed to assemble components of furnishings or vehicle interiors. Within the construction industry, adhesive fabric spray is utilized for carpet or insulation installation. These adhesives enhance business operations by boosting productivity, curtailing labor expenses, and forging a dependable bond that augments the lifespan and sturdiness of the end product.

Functions of Glue Spray

The fundamental role of glue spray is to fuse two surfaces with a durable, enduring grip. It is crafted for simplicity, featuring a dispensing system that ensures an equitable distribution of the adhesive. Specialized uses include glue spray 3m variants suitable for lightweight materials as well as more demanding tasks that call for a firmer hold, such as automotive repairs or substantial fabrications.

Features of Glue Spray

Glue spray products boast an array of attributes tailored to specific requirements. For example, 3m spray glue adhesive is prized for its rapid curing and moisture resistance, ideal for scenarios where speed and endurance are paramount. The hallmarks of these sprays often encompass their user-friendliness, the caliber of the bond they forge, and their versatility in diverse applications.

Benefits of Glue Spray

The advantages of employing glue spray include the provision of a robust bond in a swift and effective manner. This translates into time and cost efficiencies for businesses. Moreover, the adaptability of spray glue adhesive means it can serve an array of sectors, from automotive to fashion, enhancing its status as a versatile product.

How to Use Glue Spray Effectively

To maximize the efficacy of glue spray, it is crucial to start with clean, dry surfaces. Vigorously shake the can, maintain the recommended distance, and apply a uniform layer. For delicate textiles, a textile glue spray with a gentle mist is optimal, whereas a more potent cloth adhesive spray is preferable for heftier materials. Always conduct a preliminary test on a small section to confirm compatibility.

How to Choose the Right Glue Spray

Choosing the appropriate glue spray hinges on the materials to be joined and their exposure conditions. For exterior applications, opt for a water-resistant and temperature-proof 3m adhesive spray glue. For fine textiles, select a fabric spray glue adhesive that is both mild and efficacious.

How to Clean and Maintain Glue Spray Nozzles

Proper cleaning and upkeep of glue spray nozzles are vital for the product's longevity. Post-use, invert the can and spray until only the propellant is emitted, clearing any lingering adhesive. Storing in a temperate, arid place is advisable to avert blockages and preserve the glue's quality.

How to Install Components with Glue Spray

In the assembly of components with glue spray, apply the adhesive to one or both surfaces as directed. Press firmly to secure a solid bond. Allow the adhesive ample time to set before applying any stress to the bond.

Target Audience and Meeting Needs

The intended market for glue spray products is extensive, encompassing professional to hobbyist users. For experts in automotive or construction fields, items like 3m spray glue adhesive fulfill the demand for a resilient, long-lasting bond. For artisans and DIY aficionados, a mod podge spray provides the simplicity and neat finish they seek.

How does glue spray ensure a strong hold?

Glue spray guarantees a formidable hold through its composition, often incorporating synthetic rubber for suppleness and robustness. The aerosol's fine mist application ensures a homogenous layer of adhesive, yielding a more consistent bond than traditional glue methods. The 3m spray on glue is especially noted for its industrial-strength grip, rendering it a trustworthy option for rigorous applications.

Is the adhesive suitable for all fabric types?

Although glue spray for fabric is engineered for versatility, pre-application testing on a discreet area is always prudent. Certain sprays are more apt for robust fabrics, while others are tailored for more delicate materials. Formulations like headliner adhesive glue are specifically concocted to adhere well with the typically denser automotive headliner textiles.

What safety precautions should be taken when using spray adhesives?

When handling any glue spray, safety is of the essence. Employ the product in a space with ample ventilation to prevent fume inhalation. Donning protective gloves and eyewear is advisable to avoid contact with skin and eyes. Adhering to the manufacturer's guidelines for usage and safety, as with 3m adhesive spray glue products, is essential for a secure and effective application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4