Foil Bubble Insulation: An Overview

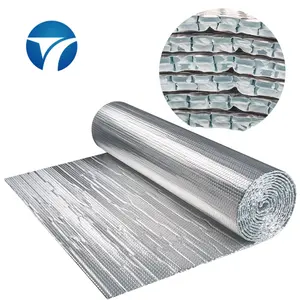

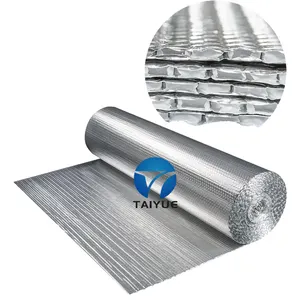

Foil bubble insulation, a modern solution for thermal regulation, stands as a testament to innovation in insulation technology. This material is crafted by bonding layers of aluminum foil with bubble wrap, creating a barrier that reflects heat and provides exceptional thermal resistance. The unique structure of foil bubble wrap insulation makes it a versatile choice for a variety of settings, ensuring spaces remain temperature-controlled and energy-efficient.

Composition and Types

The composition of foil bubble insulation typically involves two main materials: aluminum foil and polyethylene bubbles. These components work in tandem to offer insulation against external temperature changes. Among the variations available, double bubble foil insulation and double bubble insulation foil provide enhanced performance with two layers of bubbles sandwiched between foil, suitable for more demanding applications. Aluminium bubble foil is another variant, recognized for its lightweight yet robust nature.

Applications and Effectiveness

The applications of foil bubble insulation are diverse, ranging from residential to industrial settings. It is commonly used in roofing systems, where reflective bubble insulation can prevent heat ingress, and in walls, where it acts as a thermal barrier. The effectiveness of this insulation is often measured in terms of double bubble insulation R value, indicating its resistance to conductive heat flow, with higher values signifying greater insulating power.

Features and Advantages

Foil bubble insulation is not only a thermal shield but also comes with additional features that enhance its utility. It is inherently water-resistant, making it suitable for environments where moisture is a concern. The lightweight nature of bubble wrap with foil makes it easy to handle and install. Moreover, the thermal bubble wrap variant offers a dual function of cushioning and insulation, ideal for packaging needs.

Materials and Sustainability

The materials used in the production of foil foam insulation and bubble insulation sheet are chosen for their durability and environmental impact. The aluminum foil is recyclable, and the entire product is designed to be eco-friendly, reducing the carbon footprint of buildings where it is installed. This commitment to sustainability is evident in the growing preference for these materials in green construction projects.

Choosing the Right Insulation

Selecting the appropriate foil bubble wrap insulation involves considering the specific requirements of the project. Factors such as the desired R-value, the type of surface to be insulated, and environmental conditions play a crucial role in determining the most suitable product. Whether it's for a commercial facility or a residential home, the right insulation can lead to significant energy savings and improved comfort.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4