Introduction to Flexible PCB Boards

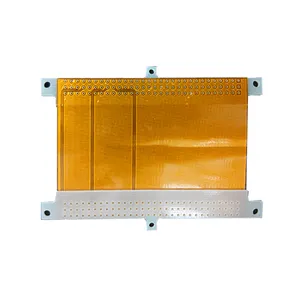

Flexible PCB boards, or flexible printed circuit boards, are a pivotal innovation in the realm of electronic components. These boards are designed to flex and conform to different shapes and configurations, which is a significant departure from the traditional rigid PCBs. This flexibility opens up new possibilities for designers and engineers, allowing for more creative and compact product designs.

Types and Applications of Flex PCBs

The applications of flex circuit boards are diverse, ranging from intricate telecommunications equipment to the simplicity of children's toys. The versatility of flex pcbs stems from their ability to integrate into various devices, regardless of shape or size constraints. In the medical field, for instance, their lightweight and flexible nature make them ideal for wearable devices. Similarly, in the automotive industry, flexible circuit board manufacturers have revolutionized design by providing solutions that withstand harsh environments and fit into tight spaces.

Features and Materials

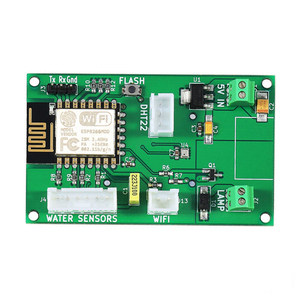

A flexible pcb is typically composed of a flexible polymer substrate, onto which a conductive copper circuit is printed. The choice of materials is crucial, as it must not only conduct electricity efficiently but also endure bending and folding without compromising performance. The construction of a flex pcb board may involve multiple layers, each adding to the complexity and functionality of the board. The materials used must also be compatible with the soldering patterns and surface finishing techniques that ensure reliable connections.

Advantages of Flexible Circuit Boards

One of the primary advantages of flex circuit pcb units is their adaptability. The high adaptability of terminal pins in these boards ensures a seamless flow of signals, which is essential for maintaining the performance of high-frequency electronic devices. Moreover, the durability of flexible pcb boards is a testament to their construction, which can withstand repeated flexing and movement. This resilience makes them a preferred choice in industries where reliability is paramount.

Choosing the Right Flex PCB

When selecting a flex circuit board, it is essential to consider factors such as board size, thickness, and copper thickness, which should align with the specific requirements of the device in question. The type of layering dictates the connectivity options and should be chosen based on the intended application. Additionally, the integrated capacity of the board must be sufficient to ensure a free flow of transmission frequencies without interference.

Trust and Transparency in Flex PCB Purchasing

Alibaba.com hosts a comprehensive catalog of flex pcb manufacturers, enhancing trust and transparency for business buyers. The platform connects buyers with a global market of suppliers, offering a variety of rigid flex pcb and flexible circuit board options. While navigating through the offerings, it is crucial for users to assess the compatibility of the boards with their electronic items, focusing on the technical specifications rather than promotional claims.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4