Upgraded Air Cushion Machine Protective Packaging Film Bubble Warp Machine

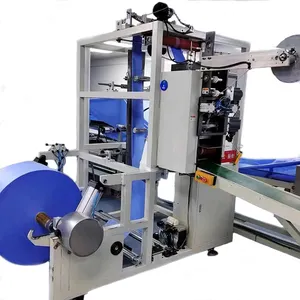

New Automatic Nonwoven Fabric Folding Machine Side Adhesive Nonwoven Drapes Folding Equipment Motor Non Woven Making Machine

Hottest Selling 16 Spindle Shoelace Cords Rope Elastic Cord Braided Flat Shoe Laces Braiding Machine Straw Rope Braiding Machine

Full Automatic Grade PET Packing Tape Band Production Line Making Equipment/pet Strap Band Tape Making Machine Customer Choice

High Quality Hydraulic PP Belt Bale Press And Banding Machine

Tubular Wire Stranding Machine China Factory Manufacturing Cheap Tubular Steel Wire Rope Stranding Machine

Yitai Belt Needle Loom Textile Knitting Machinery Price Medical Gauze Elastic Tape Making Machine Narrow Fabric Weaving Machine

GINYI Computerized Jacquard Webbing Elastic Band Needle Loom Machine Boxer Elastic Logo Band jacquard looms machine price

GINYI Belt Needle Loom Textile Knitting Machinery Price Elastic Tape Making Machine Narrow Fabric Weaving Machine GNN-2/110

Factory price underpants elastic tape/band making machine+automatic curtain tape weaving loom

Plain Elastic Heavy Type Belt Weaving Machine Price

Belt Needle Loom Textile Knitting Machine Price Elastic Earloop Making Machine Weaving Machine

Used Mini Power Loom Elastic Webbing Making Machine Price

Factory Direct Price Industrial Elastic Webbing Webbing Sling Loom Machine

Zhengtai Electronic Jacquard Loom Machine Looms Price Narrow Tape Needle Jacquard Elastic Band Machine For Men's Shorts Belt

A one-year warranty core parts elastic yarn warping machine price preferential spandex warping machine

Webbing sewing needle loom elastic webbing machine price

Computerized Jacquard Needle Loom Elastic Tape Weaving Machine Price

Factory Direct Sale Low Price Elastic Band Computer Controlled Elastic Webbing Machine

Factory Supply Attractive Price Elastic Band Electronic Jacquard Machine

Elastic Bandage Machine Power Loom Price In Pakistan Webbing Weave Machine

Yoga Braided Elastic Band Weaving Crochet Machine Price

YongJin High speed elastic machine price+jacquard elastic tape making machines

48 Spindle Elastic Band Machine Textile Machinery Braiding Machine price

Computerize Electronic Jacquard Loom Machine Jacquard Label Weaving Loom Machine

Factory price high speed automatic loom machine

Best price wristband needle loom weaving machine

automatic edge alignment knit and woven fabric inspection and relaxing machine

Jacquard Webbing Elastic Band Needle Loom Machine Boxer Elastic Power Jacquard Loom Weaving Machine

65-1 series high speed flat belt braiding machine

GINYI Manufacture Factory 39 spindle Braiding Machine steel Wire Knitting Shoelace Machine Shoelaces Braiding Machine Low Price

Best selling straw weaving machine/Reed mat knitting machine/straw braiding machine with low price

Yishuo Flat Elastic Harness Braiding Machine High Hardness Cords Lace Braiding Machine Badminton Stringing Machine

Wholesale price 6-cylinder narrow ribbon and elastic finishing ironing machine

GINYI Factory Hot Sale Good Price Elastic Weaving Machine High Speed Needle Loom Machine Tape Ribbon Making Machine for Sale

GINYI GNN-2/110 Model Textile Knitting Machinery Price Medical Gauze Elastic Tape Making Machine Narrow Fabric Weaving Machine

Competitive price automatic cotton elastic belt machines+elastic making machine in pakistan

Yitai Automatic Loom Weaving Machine Elastic Machine Price Tape Making Machine

Elastic Webbing Machine Needle Power Loom Machine Price

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4