Introduction to EDM Drilling Machines

Electrical Discharge Machining (EDM) drilling machines, also known as spark eroding, die sinking, or wire erosion equipment, are highly specialized tools used in the manufacturing industry. These machines are designed for creating precise holes and are particularly effective for hard materials that are difficult to machine with traditional methods.

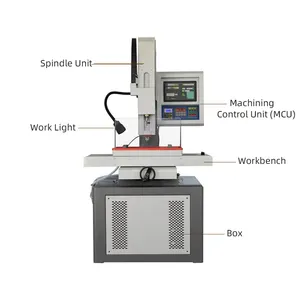

Components and Design

An EDM drilling machine comprises several critical components, each serving a unique function in the drilling process. The drill head, which houses the electrode and dielectric fluid, is pivotal for the machining operation. The base provides stability, while the column supports the machine's table and head. The table, equipped with T-slots, secures the workpiece during operation. The radial arm, which facilitates movement and positioning of the drill head, is essential for precision.

Types of EDM Drilling Machines

The versatility of EDM technology has led to the development of various machine types, including small hole drilling machines and micro hole drilling machines. These specialized machines cater to different industry needs, from creating minute holes with high precision to handling larger, more complex projects.

Applications and Advantages

EDM drilling machines are indispensable in industries requiring meticulous detail and precision. They are commonly used for making intricate holes, with applications extending to aerospace, medical, and automotive sectors. The advantages of using an EDM drilling machine include its ability to machine complex shapes and hard materials with accuracy and minimal physical effort.

Materials and Features

These machines are capable of handling a variety of materials, including hardened steel, exotic metals, and alloys. Features such as hole popper electrodes enhance the machine's capabilities, allowing for the efficient creation of deep, small-diameter holes with excellent surface finish.

Choosing the Right EDM Drilling Machine

Selecting the appropriate EDM drilling machine, such as the agie charmilles drill 20, depends on the specific requirements of the task at hand. Factors to consider include the size of the holes to be drilled, the type of material, and the desired precision. Alibaba.com hosts a diverse array of options to meet various operational demands without endorsing any particular brand or making absolute claims about the products available through its platform.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4