An edging press machine is a specialized device designed to streamline the process of applying edges to various board materials in manufacturing settings. These machines are pivotal in the production of furniture, providing high-precision edging solutions for materials like MDF, plywood, and particle board. The edging press machine has evolved to become a critical component in the woodworking and furniture manufacturing industries, offering a blend of efficiency and accuracy that is essential for modern production demands.

Types of Edging Press Machines and Their Characteristics

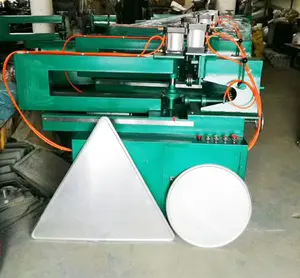

Edging press machines come in various types, each designed to meet specific needs within the industry. Speed-adjustable portable small circular board edge banding machines are ideal for on-site work and small workshops, offering flexibility and ease of transport. For larger operations, the 30-50 layers woodworking edge glue plywood hot press machines provide the capability to handle high-volume tasks with consistent quality. Furniture tabletop trimming edge double press woodworking edge banding machines cater to more complex edging needs, allowing for precision in double-sided applications. Each type of machine brings its own set of characteristics, such as speed, precision, and capacity, making the selection process critical to match the specific requirements of the production line.

Detailed Structure of an Edging Press Machine

The physical structure of an edging press machine is a marvel of engineering, consisting of several key components. The raw water tank is where the material is initially placed. From there, the motor powers the system, driving the gears and bearings that facilitate smooth operation. The PLC acts as the brain of the machine, allowing for precise control and adjustments during the edging process. The heater and evaporator work in tandem to prepare the edges of the material, while the condenser and collector play crucial roles in the finishing stages. Understanding how these components operate together is essential for operators to achieve the best results from their edging press machine.

Materials Used in Edging Press Machines and Their Properties

The materials used in the construction of an edging press machine are selected for their durability and performance. High-grade steel is commonly used for the frame and structural components due to its strength and longevity. The motor and gears are often made from specialized alloys that provide the necessary torque and wear resistance for continuous operation. PLCs are typically housed in industrial-grade plastic casings to protect from electrical interference and environmental factors. The choice of these materials ensures that the edging press machine can withstand the rigors of heavy use while maintaining precision and efficiency.

Business Usages and Applications of Edging Press Machines

In the realm of business, edging press machines are used across various industries, from furniture manufacturing to construction. In manufacturing plants, these machines are integral in the production of cabinets, tables, and shelving, providing the fine finishes that are critical for product quality. Building material shops utilize these machines to customize materials for construction projects, enhancing the aesthetic and functional properties of the end products. The ability of these machines to improve product quality and production efficiency has made them valuable assets in creating business value and supporting the growth of manufacturing capabilities.

Functions Performed by an Edging Press Machine

An edging press machine is designed to perform a range of tasks to meet the diverse needs of the woodworking and furniture production industries. Its primary functions include fine trimming, which ensures a smooth, clean edge; corner trimming for precise edge finishes; end trimming to create uniform lengths; and buffing to polish the edges for a high-quality finish. These functions are essential in the production of furniture and wood products, as they directly affect the aesthetics and structural integrity of the final product.

Distinct Features of an Edging Press Machine

The distinct features of an edging press machine include its high-accuracy and competitive price point. These machines are engineered to provide precise edging without the high costs associated with more complex machinery. The multifunctional nature of these machines allows them to handle a variety of edging tasks, making them a versatile addition to any production line. Their ease of operation reduces the learning curve for new operators, further adding to their appeal.

Benefits Offered by an Edging Press Machine

The benefits of using an edging press machine are manifold. They solve the problem of inconsistent edging in manual processes, ensuring that each piece meets strict quality standards. The positive outcomes include improved product appearance, enhanced durability, and increased customer satisfaction. For the user, these machines offer a reduction in labor costs and production time, leading to improved efficiency and profitability.

How to Effectively Operate an Edging Press Machine

Operating an edging press machine effectively requires understanding its components and functions. Starting with the selection of the right machine, operators should consider the specific needs of their production, such as the types of materials they will be working with and the volume of production. Once the appropriate machine is chosen, following the manufacturer's guidelines for operation, cleaning, and maintenance will ensure the machine performs at its best. Regular cleaning and maintenance are crucial to prevent downtime and extend the life of the machine. Installation should be carried out by professionals to ensure that the machine is set up correctly and safely.

Target Audience and Meeting Their Needs

The target audience for different types of edging press machines varies based on the specific applications and capacities of the machines. Small to medium-sized woodworking shops may opt for portable or smaller machines that offer flexibility and are cost-effective. Larger manufacturing plants may require heavy-duty machines that can handle high volumes and offer a wider range of functions. Understanding the needs and preferences of these target audiences is key to providing them with a machine that not only meets their production requirements but also offers ease of use and reliability.

What After-Sales Services Can You Expect?

When purchasing an edging press machine on Alibaba.com, buyers can expect comprehensive after-sales services. These services may include online support, video technical support, and the availability of engineers to service machinery overseas. Additionally, field maintenance and repair services, as well as overseas third-party support, are often available, ensuring that buyers have the necessary support to keep their machines running smoothly.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4