Understanding Cylindrical Grinding Wheels

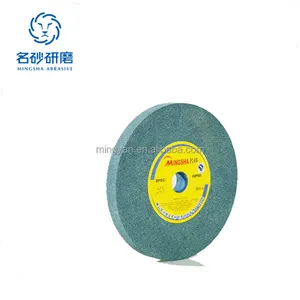

Cylindrical grinding wheels are specialized tools used in the manufacturing process to shape and finish the exterior of cylindrical objects. These wheels are essential in various industries, providing precision and smoothness to the surfaces they refine. The selection of a cylindrical grinding wheel is critical, as it influences the quality and pace of the grinding operation.

Types and Applications

There are several types of cylindrical grinding wheels, each designed for specific materials and applications. Wood grinding wheels are tailored for woodworking tasks, while aluminum grinding wheels are best suited for aluminum components. For tougher materials like metals, a dedicated metal grinding wheel is the preferred choice. These variations ensure that for every material, there is an optimal wheel to achieve the desired finish.

Features and Materials

The construction of a cylindrical grinding wheel determines its suitability for certain tasks. Diamond grinding wheels, known for their durability and cutting prowess, are composed of diamond particles and are ideal for handling hard materials such as stone, concrete, or brick. The features of these wheels, including grain size, bond type, and wheel grade, are fine-tuned to cater to specific grinding requirements.

Advantages of Precision Tools

Using the correct grinding wheel offers numerous advantages, such as improved efficiency and a higher-quality finish. The precision of a cylindrical grinding wheel allows for the removal of imperfections and burrs, resulting in a superior surface finish. Moreover, the versatility of angle grinder wheels, which can cut, deburr, grind, or sand, makes them invaluable in a variety of settings.

Selecting the Right Grinding Wheel

Choosing the appropriate cylindrical grinding wheel is a nuanced decision that depends on the intended operation and the material of the workpiece. Factors to consider include the hardness of the material, the desired finish, and the speed of operation. It is crucial to match the wheel to the job to ensure optimal performance and longevity of the tool.

Conclusion

In conclusion, the cylindrical grinding wheel is a fundamental component in precision manufacturing. Its ability to shape and finish materials with accuracy makes it indispensable in industrial settings. By understanding the different types, applications, and features of these wheels, users can select the most suitable product for their specific needs, ensuring a smooth and efficient grinding process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4