Introduction to Cutting Machine Chamfer Technology

The realm of manufacturing and assembly often requires precision in creating angled surfaces on edges, a process known as chamfering. A cutting machine chamfer is a specialized tool designed to perform this task, ensuring that edges are not only smooth but also shaped to meet specific requirements. This technology is pivotal in various industries, from plumbing to furniture making, and plays a crucial role in preparing materials for final use or further manufacturing processes.

Types and Applications of Chamfering Machines

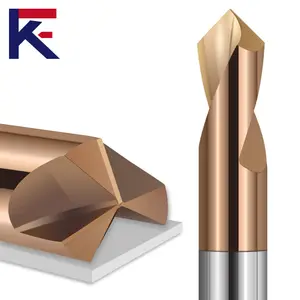

Chamfering machines come in various forms, each suited to particular materials and applications. For instance, chamfer end mills are typically used in metalworking to provide a finished look and to ease the assembly of parts. On the other hand, a ceramic tile chamfer machine is designed to address the brittle nature of tiles, ensuring a smooth, angled edge for a clean finish in tiling projects. The versatility of a chamfer cutting machine extends to creating beveled edges on wood, glass, and even concrete, showcasing its wide-ranging utility in industrial and creative endeavors.

Features of Chamfer Cutting Machines

The features of a cutting machine chamfer are diverse, catering to the needs of different materials and scales of operation. These machines may vary in RPM rates, chamfer sizes, and power ratings, allowing for customization to the task at hand. Whether it's for large-scale production or fine, detailed work, the machine's specifications are crucial in achieving the desired chamfering effect on the material being processed.

Materials Compatible with Chamfer Machines

A cutting machine chamfer is not limited to a single material. Its adaptability allows for reshaping a multitude of materials such as plastic, wood, and metal. Plastic piping, for example, can be efficiently chamfered to create connectors that fit seamlessly within pipe networks. Similarly, the precision of these machines is essential in the finishing touches for wooden furnishings, where a smooth, angled edge can significantly enhance aesthetic appeal.

Advantages of Using Chamfer Machines

The use of chamfer machines in manufacturing and finishing processes offers numerous advantages. These machines provide a consistent and accurate method to create beveled edges, which is essential for the integrity of connections in piping systems or the safety of consumer products like toys. Moreover, the efficiency of a chamfer cutting machine in creating these finishes can lead to increased productivity and a reduction in manual labor.

Selecting the Right Chamfer Machine

Choosing the correct chamfer machine is crucial for meeting the specific needs of a project. Factors to consider include the material to be chamfered, the required precision, and the scale of production. Alibaba.com offers a platform where a variety of chamfer machines are available, allowing buyers to connect with suppliers and find the equipment that best fits their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4