Introduction to Cosmetic Capping Machines

Cosmetic capping machines are essential equipment in the packaging industry, specifically tailored for sealing various types of cosmetic products. These machines ensure that containers are securely sealed to maintain product integrity, extend shelf life, and provide a professional finish. The versatility of these machines allows them to handle a range of container sizes and shapes, making them a valuable asset for businesses looking to enhance their packaging operations.

Types of Cosmetic Capping Machines

The cosmetic industry utilizes a variety of capping machines, each designed to cater to different packaging needs. Automatic capping machines are ideal for high-volume production, ensuring speed and consistency in the capping process. Handheld capping devices offer portability and convenience for small batches or on-the-go adjustments. For operations that fall in-between, benchtop cappers provide a balance of automation and flexibility, suitable for medium-scale production needs.

Applications and Features

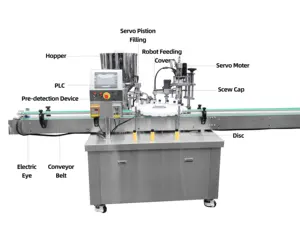

Cosmetic capping machines are not one-size-fits-all; they are designed to accommodate a wide range of cosmetic products, from skincare creams to fragrances. Key features often include adjustable torque settings, which ensure the right seal tightness without damaging the container or the cap. Additionally, many machines come with customizable cap feeders and chutes to handle various cap styles and sizes, from simple screw caps to intricate pump dispensers.

Materials and Advantages

Durability is a hallmark of a well-constructed cosmetic capping machine, with stainless steel being a common material due to its resistance to corrosion and ease of cleaning. The use of high-quality materials contributes to the longevity and reliability of the machinery. The primary advantage of using these machines is the significant increase in production efficiency, reducing labor costs and minimizing human error.

Choosing the Right Machine

Selecting the appropriate cosmetic capping machine requires an understanding of your specific production needs. Factors such as container and cap type, production volume, and available workspace all play a role in determining the most suitable machine. Whether you require a single-head capping unit for small-scale production or a multi-head capping system for larger operations, it's important to assess the features that align with your objectives.

Enhance Your Production with Alibaba.com

Explore the extensive selection of cosmetic capping machines on Alibaba.com to find the equipment that aligns with your production requirements. With a diverse range of machines available, you can identify the solution that will integrate seamlessly into your existing production line, elevating your packaging process to new levels of efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4