Understanding the Core for Transformer

Transformers are integral components in modern electrical systems, and the core for transformer is at the heart of their operation. This core, typically made of high-permeability material, is crucial in ensuring efficient magnetic flux distribution in transformers. The selection of a transformer core is dependent on the specific needs of the application, whether it's for industrial heavy machinery or residential appliances.

Types of Transformer Cores

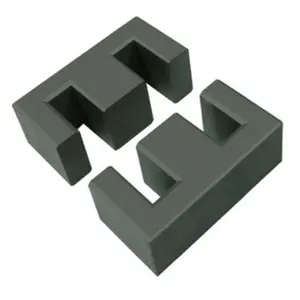

The construction of transformer cores varies, with core type transformer and shell type transformer being the primary configurations. Core type transformers are characterized by their winding encircling the core, while shell type transformers have the core surrounding the windings. Each design has its unique advantages and is chosen based on the application's demands.

Material Considerations in Transformer Cores

Materials play a pivotal role in the performance of transformer cores. Ferrite core transformers are popular for their high magnetic permeability, making them suitable for high-frequency applications. On the other hand, amorphous core transformers, known for their low power losses, are ideal for applications where energy efficiency is a priority. Laminated core transformers are widely used to reduce eddy current losses, and iron core transformers are favored for their robustness and durability in heavy-duty applications.

Applications and Features

The application of a transformer core is as varied as its types. For instance, amorphous steel core transformers are often used in power distribution networks due to their efficiency at lower loads. In contrast, air core transformers are typically employed in radio frequency applications. The toroidal transformer core, with its donut shape, is preferred for compact designs due to its efficiency and reduced electromagnetic interference.

Selecting the Right Transformer Core

Choosing the correct core of the transformer involves considering phase requirements, voltage, kVA ratings, and frequency needs. For heavy industrial equipment, a three-phase transformer core is often necessary, while single-phase cores suffice for residential use. Additionally, the core must be compatible with the frequency used in the region of operation, such as 60 Hz in the US or 50 Hz in the UK.

Environmental and Placement Factors

The environment where the transformer will operate is also a critical consideration. Cores designed for outdoor use must withstand environmental factors like moisture and temperature fluctuations. Placement is equally important, as the core must be sized and designed to fit the intended location, whether it's indoors, outdoors, or in areas with hazardous substances.

Alibaba.com hosts a diverse range of transformer cores to meet various application needs. By navigating the platform, buyers can connect with suppliers to find the appropriate transformer core without the hassle of traditional procurement methods.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4