Introduction to Concrete Wall Panel Moulds

Concrete wall panel moulds are essential tools in the construction and architectural industries, enabling the production of durable and versatile concrete panels. These moulds are designed to shape and support concrete until it hardens and can be used to create a variety of textures and designs for both structural and decorative applications.

Types and Applications

Pre-cast concrete moulds and tilt-up panel moulds are two primary types utilized in the industry. Pre-cast moulds are used in a controlled factory environment, allowing for precise and consistent panel production. Tilt-up moulds, on the other hand, are erected on the construction site itself, where the concrete is poured and lifted into place once cured. These moulds cater to a range of applications, from residential and commercial buildings to industrial structures, providing an efficient solution for rapid construction.

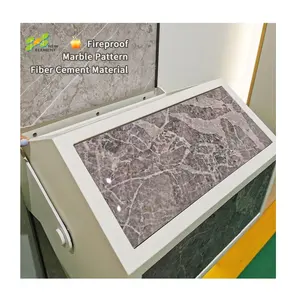

Features and Materials

The design features of concrete formwork moulds include modularity and adaptability to various architectural requirements. Materials used in mould construction are selected for their durability and resistance to the stresses of concrete curing. Common materials include steel, ABS plastic, and fiberglass, each offering distinct advantages in terms of longevity and surface finish.

Advantages of Using Concrete Wall Panel Moulds

Utilizing concrete wall panel moulds in construction projects offers numerous benefits. These moulds provide a cost-effective method for producing panels, as they can be reused multiple times, reducing material waste. Additionally, the ability to pre-fabricate panels in a controlled environment enhances the quality and precision of the final product.

Customization and Standardization

Customization is a key aspect of concrete panel moulding, allowing for the creation of unique designs and textures. Suppliers on Alibaba.com can assist in tailoring moulds to specific project requirements, ensuring the final concrete panels meet the desired specifications. Standardization of certain mould elements, such as lift bars and clamp slots, can further streamline the manufacturing process, making panel production more efficient.

Choosing the Right Mould

Selecting the appropriate concrete wall panel mould is crucial for project success. Factors to consider include the size and complexity of the panel, the desired texture, and the production environment. Alibaba.com hosts a diverse range of moulds and expert suppliers who can guide buyers in making an informed decision, ensuring that the chosen mould aligns with their project needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4