Introduction to Cold Punching Machines

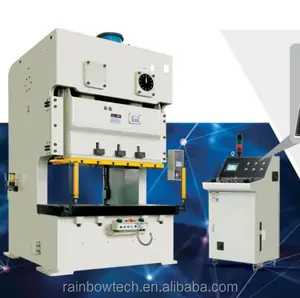

Cold punching machines are essential tools in the fabrication industry, designed for creating holes or shapes in sheet material with precision and efficiency. These machines operate without the need for heat, maintaining the integrity of the material being worked on. The technology behind cold punching machines has evolved to meet various industrial requirements, offering a range of functionalities from simple manual operations to complex CNC-controlled systems.

Types and Applications

The versatility of cold punching machines is evident in their various types. Hydraulic and pneumatic systems offer power and efficiency, while manual punches cater to more straightforward, less frequent tasks. CNC punching units are the pinnacle of innovation, allowing for intricate designs and high-volume production. These machines serve multiple sectors, from automotive to electronics, where precision metalworking is paramount.

Features and Materials

Cold punching machines are designed to handle a diverse range of materials, including metals, plastics, and composites. Features may include servo drives for enhanced accuracy, and the ability to handle different thicknesses and types of sheet material. The construction of these machines often involves robust materials like steel and iron, ensuring durability and longevity.

Advantages of Modern Punching Technology

The modern cold punching machine offers significant advantages in terms of speed, accuracy, and versatility. Automation in punching equipment reduces manual labor and increases consistency in mass production. Moreover, the adaptability to various materials and shapes makes these machines invaluable for custom manufacturing projects.

Selecting the Right Machine

Choosing the appropriate cold punching machine involves considering factors such as material type, thickness, and the scale of production. Alibaba.com's extensive catalog provides access to a selection that meets diverse industrial needs without the constraints of brand or price promotions, ensuring a focus on the specifications and capabilities that matter most to buyers.

Integration with Industrial Processes

Incorporating a cold punching machine into an industrial assembly line can streamline operations, enhancing productivity. Portable punches extend this capability to on-site repairs and projects requiring mobility. The integration of these machines into existing workflows is facilitated by their compatibility with various industrial standards and requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4