Introduction to Coating Systems

Coating systems encompass a broad range of equipment designed to apply protective and decorative layers to metal surfaces. These systems are integral to industries that require durable finishes, such as outdoor furniture production and automotive manufacturing. The application of a coating can enhance a product's appearance, increase its resistance to environmental factors, and extend its lifespan.

Powder Coating Equipment

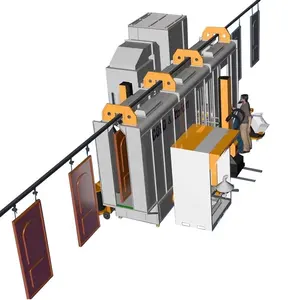

Among the various types of coating systems, powder coating equipment stands out for its efficiency and eco-friendliness. This equipment employs a dry finishing process where a powder material is applied to a surface and then cured under heat to form a skin-like layer. This method is favored for its ability to produce a tough, uniform finish that maintains color fidelity over time, making it suitable for items exposed to harsh weather conditions.

Electrostatic and Vacuum Coating Technologies

For applications requiring a thinner, yet robust coating, vacuum coating machines offer an alternative. Utilizing thin film deposition, these machines apply a slender layer that provides protection without altering the item's dimensions significantly. This is particularly important in the manufacturing of precision tools. Electrostatic paint coating machines, on the other hand, are adept at covering complex shapes uniformly, which is essential in automotive production.

Specialized Coating Solutions

The market also offers specialized solutions such as silicone roof coating and concrete epoxy paint, catering to the construction and maintenance sectors. Silicone roof coatings are known for their durability and weather resistance, while concrete epoxy paints provide a hard-wearing finish to floors, offering both protection and aesthetic enhancement. For those seeking a unique finish, metallic epoxy creates a shimmering, high-gloss surface that can transform any space.

Advancements in Coating Applications

Innovation in the field has led to the development of system x ceramic coating, a cutting-edge option that offers superior protection for automotive surfaces, and coal tar epoxy, which is widely used for its robust protective qualities in marine and industrial environments. Additionally, slot die coating technology has emerged as a precise method for applying thin, uniform coatings, particularly in the manufacturing of electronics and display panels.

Environmental Considerations and Efficiency

Efficiency and environmental impact are key considerations in the selection of coating systems. At home powder coating setups have become more prevalent, allowing for small-scale, environmentally conscious production. Moreover, advancements in heating paint technology have contributed to energy savings by enhancing the curing process, thereby reducing the carbon footprint of coating operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4