CNC Milling Controller: An Essential Tool for Precision

The cnc milling controller is a pivotal component in the realm of automated manufacturing, serving as the brain of computer numerical control milling machines. This device is responsible for the execution of complex tasks, ensuring precision and efficiency in various industrial applications. The controller's role extends beyond just guiding the most sophisticated machines; it's also instrumental in revitalizing existing machinery through retrofitting, such as with a retrofit cnc mill.

Types of CNC Milling Controllers

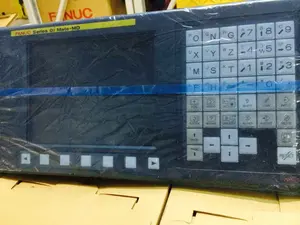

Diversity in technology offers a range of controllers suitable for different needs. From controllers that utilize the simplicity and versatility of Arduino to those that are compatible with Fanuc cnc milling machine systems, the options are vast. For those seeking advanced capabilities, the Fanuc cnc mill controllers provide robust solutions, while the Acu Rite MillPWR series caters to users looking for user-friendly interfaces and reliable performance.

Applications and Features

Controllers are not one-size-fits-all; specific models like the Prototrak mill are designed for particular machine types, offering 4-axis control and compatibility with lathes, grinders, and mills. Features such as the Prototrak SMX enhance user control, allowing for intricate and precise cuts, while the Centroid CNC mill controllers are known for their ease of use and advanced programming capabilities.

Materials and Advantages of CNC Controllers

The construction of CNC controllers involves durable materials that can withstand the rigors of industrial environments. The integration of a cnc milling controller into a computer numerical control milling machine not only boosts precision but also enhances the machine's longevity, offering a significant advantage in terms of both performance and cost-efficiency.

Complementary Components

In addition to the core controller units, complementary components such as stepper motors play a crucial role. These motors, compatible with various controllers like the Mysweety 3018 Pro, provide additional torque, enhancing the machine's control over workpiece positioning. For those inclined towards DIY, controller kits, including models like the Titoe 3018pro, come equipped with all necessary components, allowing for full customization and optimization of CNC machinery.

Choosing the Right CNC Milling Controller

Selecting the appropriate cnc milling controller is essential for achieving desired outcomes in CNC machining. Whether it's upgrading to a Fanuc mill for its renowned reliability or opting for a Prototrak CNC mill for its precision, the choice depends on the specific requirements of the task at hand. It's crucial to consider the compatibility with existing machinery, the skill level of the operating team, and the specific features that will enhance the manufacturing process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4