CNC Machine Tool Magazine Overview

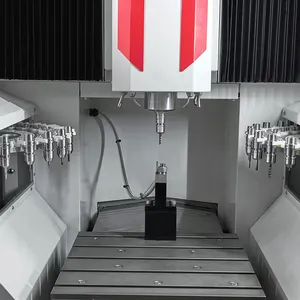

A CNC machine tool magazine is an integral component of machining centers, serving as a storage and transfer system for various cutting tools. It is essential for automating the tool changing process, enhancing the efficiency and precision of CNC machines. This category encompasses a variety of designs tailored to different machining requirements, including chain-type, drum-type, and carousel-type magazines.

Types and Configurations

The diversity in CNC machine tool magazines caters to the specific needs of different machining operations. Chain-type magazines offer a large storage capacity, making them suitable for complex tasks requiring numerous tools. Drum-type magazines provide a compact and speedy solution for quicker tool changes, whereas carousel-type magazines strike a balance between size and tool capacity. Each type ensures the seamless operation of CNC machines by providing the right tool at the right time.

Applications and Features

CNC tool changer magazines are pivotal in industries where precision and speed are paramount. They are widely used in automotive, aerospace, and metalworking sectors. The features of these magazines include robust construction for durability, precision engineering for accurate tool selection, and compatibility with various CNC machines. Advanced sensor systems and software integration are also common, allowing for smart inventory management and minimal manual intervention.

Materials and Advantages

Constructed from materials such as hardened steel and industrial-grade plastics, CNC tool magazines are designed to withstand the rigors of continuous operation. The advantages of integrating a high-capacity tool magazine into a CNC setup include reduced downtime, increased productivity, and the ability to handle complex tasks with ease. The resilience provided by these materials ensures long-term reliability and performance consistency.

Selection Considerations

When selecting a CNC machine tool holder magazine, it is crucial to consider the machine's model, the number of tools required, and the space available within the machine. Compatibility with existing CNC systems and the ease of integration are also important factors. Buyers should focus on the magazine's capacity, tool change speed, and the robustness of its design to ensure it meets their operational demands.

Enhancing CNC Machine Functionality

In conclusion, a CNC lathe tool magazine is a vital accessory for any CNC machining center. It plays a critical role in tool management and operational efficiency. By selecting the appropriate magazine type and ensuring it is made from durable materials, machining centers can significantly improve their performance and output, leading to a more streamlined manufacturing process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4