Understanding CNC Machine Guards

CNC machine guards are essential components in the realm of industrial equipment, designed to enhance safety in various manufacturing and engineering environments. These guards serve as a protective barrier between the machine operator and the CNC machinery, which operates with high precision and speed. The importance of these guards cannot be overstated, as they are critical in preventing accidents and ensuring the well-being of personnel.

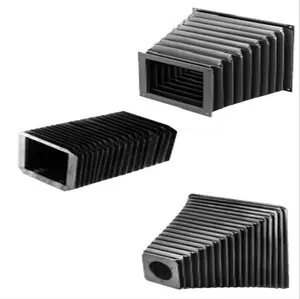

Types of CNC Machine Guards

There is a diverse array of CNC machine guards available to suit different types of machinery and applications. Some are static, providing a permanent shield around hazardous areas of the machine, while others are adjustable or even portable, offering flexibility and convenience for different tasks. Materials used in the construction of these guards include polycarbonate, metal mesh, and other durable substances, each selected for its ability to withstand the specific hazards presented by CNC operations.

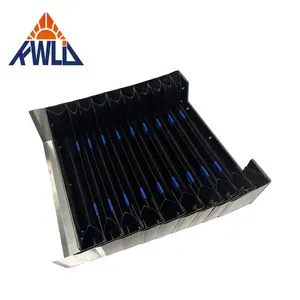

Applications and Features

The application of CNC machine guards spans across various industries, from automotive to aerospace, where CNC machinery is prevalent. These guards are not one-size-fits-all; they are tailored to the specific CNC machine, whether it's a lathe, milling machine, or router. Features of these guards include transparency for visibility, impact resistance, and sometimes interlocking mechanisms that ensure the machine operates only when the guards are properly in place.

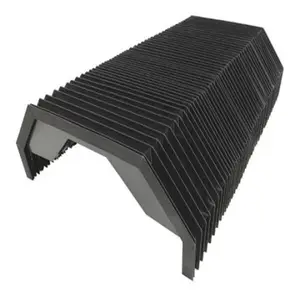

Materials and Advantages

The materials used in CNC machine guards are chosen for their durability and resistance to impacts, abrasions, and even certain chemicals. The advantages of using these guards include protecting operators from flying debris, sparks, and other potential hazards. Additionally, they help to contain the noise and dust produced by CNC machinery, contributing to a cleaner and quieter working environment.

Choosing the Right CNC Machine Guard

Selecting the appropriate CNC machine guard involves considering the specific needs of the operation, including the type of CNC machine, the level of risk involved, and the desired balance between safety and accessibility. It is crucial to assess the guard's compatibility with the machine's design and the materials being processed. The right guard not only enhances safety but also complements the efficiency of the CNC operation.

Integration with CNC Operations

Integrating CNC machine guards into the workflow requires careful planning to ensure they do not impede the operation's efficiency. Guards should be easy to install and maintain, with minimal interference in the machine's functionality. This integration is a strategic approach to maintaining productivity while upholding the highest safety standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4