CNC Foam Cutter Machine: An Overview

A CNC foam cutter machine is a specialized device engineered to slice through foam materials with precision and ease. These machines cater to a variety of industries, from packaging to construction, and are integral in shaping materials for diverse applications. The technology behind these cutters has evolved, offering different methods such as hot wire, laser, and blade systems to meet specific cutting needs.

Types of CNC Foam Cutting Technology

The CNC hot wire foam cutter is a popular choice for its efficiency in batch processing. Utilizing a heated wire, it smoothly carves through expanded polystyrene (EPS) and extruded polystyrene (XPS), making it ideal for creating architectural models or theatrical props. In contrast, the laser CNC foam cutter stands out for its ability to deliver intricate cuts with minimal residue, perfect for precision work in artistic installations or detailed product prototypes.

Applications Across Industries

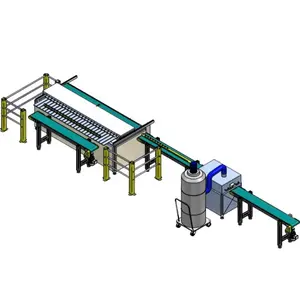

From the 3D foam cutting machine used in creative sectors to the robust CNC foam router for industrial applications, these machines serve a broad spectrum of purposes. They are instrumental in fabricating custom packaging solutions, designing comfortable furniture with precise cushioning, and even in the realm of aeronautics for creating lightweight yet sturdy components.

Features and Advantages of Advanced CNC Foam Machines

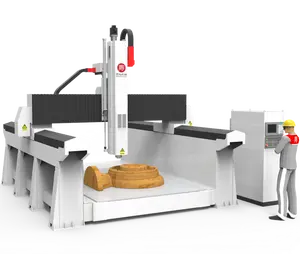

Advanced models, such as the 5 axis CNC foam cutter, offer unparalleled versatility, allowing for complex shapes and designs that were once impossible to achieve. The 4 axis foam cutter provides additional flexibility with its ability to rotate the material, enabling multi-dimensional cutting paths. These machines are not only about versatility but also about enhancing productivity with their automated and programmable capabilities.

Materials and Precision in CNC Foam Cutting

The precision of a CNC foam cutter DIY setup or an industrial-grade machine is paramount, with the ability to handle materials like EPE (expanded polyethylene) with accuracy. The cnc styrofoam cutter is specifically designed to manage the delicate nature of styrofoam, ensuring clean cuts without degrading the material's integrity.

Choosing the Right CNC Foam Cutter Machine

Selecting the appropriate cnc foam cutting machine hinges on understanding the specific requirements of the task at hand. Whether it's a 4 axis hot wire foam cutter for intricate art pieces or an arduino cnc foam cutting machine for custom DIY projects, the key is to match the machine's capabilities with the intended application to ensure efficient and precise cutting.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4