Introduction to Car Battery Production Lines

The car battery production line is an integral component of the automotive industry, designed to streamline the assembly and production of car batteries. This sophisticated machinery ensures the efficient production of batteries by automating various processes, from filling to sealing. The production line is engineered to handle a variety of tasks with precision, catering to different types of car batteries and their specific requirements.

Types and Applications

There are several types of car battery assembly lines, each tailored to accommodate different production scales and battery models. These lines are versatile, capable of processing various battery sizes for electric vehicles, commercial cars, and more. The application of these production lines extends beyond automotive to industries requiring battery use, such as renewable energy storage systems.

Features and Materials

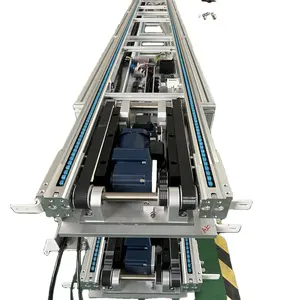

A car battery production line is characterized by its robust construction and the use of durable materials, ensuring longevity and reliability. The machinery is equipped with advanced features such as programmable logic controllers and precision dispensing systems, which are essential for maintaining consistency in battery quality. Materials used in construction are selected for their strength and compatibility with the chemicals involved in battery production.

Advantages of Automated Production

Automation in car battery manufacturing brings numerous advantages. It significantly reduces the need for manual labor, thereby minimizing human error and enhancing production efficiency. Automated lines ensure consistent product quality and faster turnaround times, which are crucial for meeting market demands. Additionally, the automation of car battery lines allows for better scalability of production as demand fluctuates.

Efficiency and Cost-Effectiveness

The efficiency of a car battery assembly line is evident in its ability to manage energy consumption while maintaining high output rates. This balance is critical for cost-effective operation, as it helps in reducing operational expenses without compromising on productivity. Furthermore, the precision in dispensing materials reduces waste, contributing to a more sustainable production process.

Customization and Versatility

Flexibility is a key feature of the car battery production line, with many systems offering customization options to suit specific production needs. This versatility ensures that a wide range of battery types can be produced on the same line, making it a valuable asset for manufacturers looking to diversify their product offerings or adjust to market changes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4