Understanding Cable Insulation Sleeves

Cable insulation sleeves are essential components in safeguarding electrical wires from external damage and wear. These protective coverings are designed to insulate a wide array of cable types, ensuring operational safety and longevity. The selection of a cable insulation sleeve should be guided by a thorough understanding of the application requirements and environmental conditions to which the cables will be exposed.

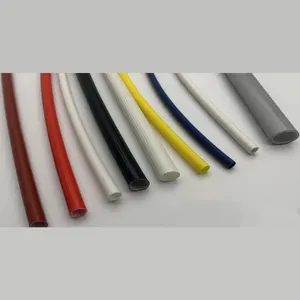

Materials and Types of Sleeving

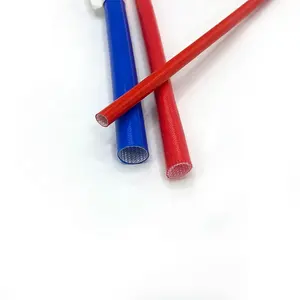

The material composition of a cable insulation sleeve is crucial, as it determines the sleeve's protective qualities. Braided fiberglass sleeving offers excellent heat resistance and durability, making it suitable for high-temperature environments. On the other hand, silicone cable sleeves provide flexibility and are often selected for applications requiring movement or bending. For electrical insulation, insulation sleeves for electrical cables made from materials like PVC or rubber are commonly used due to their dielectric properties.

Features and Applications

When it comes to applications requiring resistance to extreme temperatures, high temp wire sheathing and high temperature wire sheathing are ideal. These sleeves are engineered to withstand continuous exposure to high temperatures while maintaining their insulating properties. In environments where fire resistance is paramount, fiberglass cable sleeve options are often employed due to their non-combustible nature. For applications involving frequent cable movement, the flexibility of a braided insulation sleeve is beneficial, providing protection without compromising cable mobility.

Advantages of Proper Cable Protection

The advantages of using a cable insulation sleeve are manifold. They not only protect cables from abrasion, moisture, and chemical contaminants but also enhance the overall safety of electrical systems. Heat shrink insulation sleeves offer a snug fit and reliable insulation for splices and terminations, while heat resistant wire covering ensures that cables remain functional under thermal stress. For grounding purposes, an earth insulation sleeve can be used to prevent electrical faults and enhance user safety.

Selection Considerations

Selecting the right cable insulation sleeve involves considering the number of cables to be covered, the type of connectors in use, and the environmental conditions such as temperature and potential mechanical stress. For instance, raychem insulation sleeves are known for their reliable insulation properties and compatibility with various connector styles. Meanwhile, electrical wire fiberglass insulation sleeving is a go-to for its dielectric strength and durability.

Conclusion

In conclusion, the right cable insulation solution is paramount for the safety and efficiency of electrical systems. Alibaba.com offers a diverse range of sleeving options to meet the needs of various applications. By considering the factors outlined above, buyers can navigate the extensive selection and find the appropriate cable insulation sleeve for their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4