Introduction to Block Moulds

Block moulds are essential components in the construction industry, utilized for shaping and creating various types of blocks used in building and paving. These moulds come in different forms, such as concrete block moulds, hollow block mould, and paver block mould, each designed to meet specific requirements of strength, design, and functionality.

Types of Block Moulds

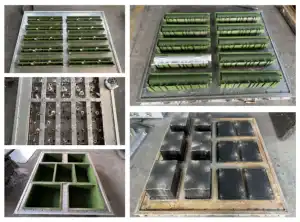

Within the category of block moulds, there are several types to consider. Cement block mould options are widely used for their durability and strength, ideal for creating standard building blocks. For those in need of intricate patterns, paver block rubber mould and plastic paver block moulds offer versatility for creating decorative walkways and patios. Interlocking moulds are another popular choice, designed to produce blocks that interlock for added stability in structures and surfaces.

Applications and Features

Block moulds serve a variety of applications, from constructing sturdy walls to paving outdoor spaces. Baseboard corner blocks and base molding corner blocks are particularly useful in finishing touches for flooring and wall junctions, ensuring a seamless transition. Corner block molding is another feature that aids in creating a polished look for various construction projects. The features of these moulds, such as their design intricacy and production capacity, are tailored to the specific needs of the project at hand.

Materials and Advantages

The materials used in block moulds, such as rubber, plastic, and metal, are chosen for their resilience and ability to replicate precise shapes and textures. Breeze block moulds, for example, are designed to produce blocks that provide both structural support and aesthetic appeal. The use of these moulds offers advantages such as cost-efficiency, repeatability, and the ability to mass-produce blocks with consistent quality.

Choosing the Right Block Mould

Selecting the appropriate block mould requires consideration of the block's intended use, the material it's made from, and the production capacity needed. For intricate designs, baseboard trim corner blocks and floor molding corner blocks moulds are ideal. It's important to review the specifications of each mould to ensure it meets the project's requirements without making assumptions about performance or compatibility.

Conclusion

In conclusion, block moulds are a fundamental tool in the construction and paving industries. Alibaba.com offers a comprehensive selection of moulds to cater to various needs, from hollow block molding for building projects to crown blocks molding for decorative purposes. By understanding the different types, applications, and materials of block moulds, buyers can make informed decisions to streamline their construction processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4