What are Bevel Gears

Bevel gears are specialized mechanical components designed for transmitting power between intersecting axes, typically at a 90-degree angle, but they can work at other angles as well. They are distinguished by their conical shape, which allows them to mesh at various angles, unlike spur or helical gears that must be parallel. Bevel gears are integral to various mechanical systems, making them essential for diverse industries from automotive to industrial machinery.

The unique geometry of bevel gears enables them to change the axis of rotational motion, which is critical in many applications where the direction of drive needs to be altered. For example, in an automobile differential, bevel gears transfer power from the driveshaft to the wheels, allowing them to rotate at different speeds during a turn. Similarly, they are used in hand drills to enable the chuck to operate perpendicular to the motor's axis.

Bevel gears operate on the principle of two toothed wheels coming into contact. As one gear (the driver) turns, its teeth push against the corresponding teeth of the other gear (the driven), thereby transferring force and motion. The efficiency and smoothness of this power transmission depend on precise gear design and manufacturing quality.

These gears come in various types to suit specific applications and operational requirements. Due to their critical role in machinery, selecting the right bevel gear is paramount for ensuring performance, longevity, and safety of operations. Manufacturers and engineers need to consider factors such as material strength, gear ratio, and tooth geometry when designing or choosing these components.

Types of Bevel Gears

Bevel gears are classified into various types depending on their tooth geometry and manufacturing methods. Each type has its characteristics and common use cases:

Straight Bevel Gears: These are the simplest form of bevel gears with straight teeth that are tapered towards the apex of the cone. Straight bevel gears are easy to manufacture and are used in applications where low speed and high torque are required.

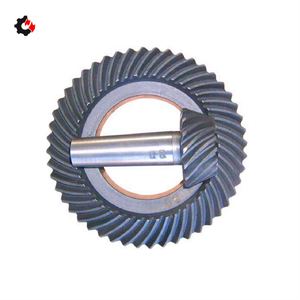

Spiral Bevel Gears: Featuring curved teeth that are angled to form an arc, these gears offer smoother operation than straight bevel gears. Spiral bevel gears are commonly used in automotive differentials where they provide reduced noise and vibration at higher speeds.

Hypoid Bevel Gears: A variant of spiral bevel gears with an offset between the shafts allows for a larger diameter gear and improved gear meshing. Hypoid gears find their applications in automotive rear axles where they contribute to better fuel efficiency and lower vehicle height.

Miter Gears: These are a special type of bevel gear with a 1:1 ratio that is used when the objective is simply to change the direction of rotation without altering speed or torque.

Zerol Bevel Gears: Zerol bevel gears are very similar to spiral bevel gears but have a zero spiral angle. They bridge the performance gap between straight and spiral bevel gears.

Each type serves a specific purpose in machinery and every industry may favor one type over another based on factors such as noise tolerance, torque requirements, and desired longevity.

How to choose Bevel Gears

Selecting the appropriate bevel gear for a business application requires careful consideration of several factors. The choice should take into account the specific demands of the machinery where the gear will be used while also aligning with business objectives such as cost-efficiency and reliability.

Material selection is crucial; options range from various metals like steel or bronze to plastics depending on load requirements and operating conditions. For high-strength applications, hardened alloys may be necessary whereas lighter duty mechanisms might benefit from plastic gears for their cost-effectiveness and quiet operation.

Tooth profile also deserves attention. Whether spiral or straight toothed, each profile caters to different operational needs — spiral bevel gears might be selected for their smoother engagement whereas straight toothed gears could suffice for simpler, lower-speed tasks.

Standard or nonstandard sizing can impact both availability and price with standard sizes typically being more readily available and potentially less expensive due to economies of scale. Nonstandard sizes might offer a better fit for specialized equipment but could incur additional costs due to custom manufacturing processes.

Finally, considering supplier capabilities including machinery test reports, after-sales service options, and whether custom support like ODM or OEM is available will ensure that businesses choose a reliable partner able to meet technical requirements while also providing ongoing support throughout the product lifecycle.

Best Bevel Gears on Alibaba.com

Alibaba.com stands out as a global marketplace connecting businesses with a vast selection of industrial components like bevel gears. It provides a platform where buyers can find suppliers equipped with diverse manufacturing capabilities catering to a wide array of industries including automotive, construction, agriculture, and many more. This variety ensures that businesses can source products that meet their specific needs whether they're looking for standard parts or require bespoke solutions through ODM or OEM services.

This platform's comprehensive filtering options allow businesses to refine their search based on material composition, tooth profile design, industry application relevance, or even processing technique — forging or casting — making it easier to narrow down their choices swiftly without compromising on requirements. Additionally, Alibaba.com's Trade Assurance service offers an extra layer of financial security by protecting payments until delivery completion ensuring that transactions conducted through the site are both secure and reliable.

For businesses looking toward international trade solutions that streamline sourcing processes while maintaining high standards of quality assurance, Alibaba.com embodies an all-in-one solution that facilitates global trade by providing access to a plethora of suppliers ready to fulfill commercial product demands efficiently. By leveraging Alibaba.com's extensive network and user-friendly platform features such as mobile accessibility and local language support, businesses can confidently venture into global markets enhancing their competitive edge.

Common FAQs for Bevel Gears

What are the primary applications of bevel gears?

Bevel gears are extensively used in various industries for transmitting power between shafts that intersect, commonly at right angles. Their primary applications include automotive differentials, industrial machinery, agricultural equipment, and aviation systems.

How do I determine the correct bevel gear type for my application?

The selection of a bevel gear type depends on factors such as the angle between the shafts, torque requirements, operating speeds, and noise constraints. Analyzing these factors can guide you toward choosing between straight, spiral, hypoid, miter, or zerol bevel gears.

What materials are commonly used in the production of bevel gears?

Bevel gears can be made from a range of materials including various steels, cast iron, stainless steel, brass, bronze, plastics, and more. The choice of material is dictated by the intended application's load capacity and environmental conditions.

Can bevel gears operate at angles other than 90 degrees?

Yes, while bevel gears are often associated with 90-degree shaft intersections, they can be designed to operate at other angles to suit specific design requirements and applications.

What is the difference between spiral and straight bevel gears?

Spiral bevel gears have curved teeth that engage gradually and smoothly whereas straight bevel gears have teeth that are straight and tapered toward the apex of the cone. Spiral bevel gears generally operate more quietly and can handle higher speeds compared to straight bevel gears.

How does the tooth profile affect the performance of a bevel gear?

The tooth profile influences how two mating bevel gears will distribute load and transmit power. Different profiles such as spiral or straight can affect the efficiency, noise level, strength, and smoothness of operation.

Are custom-designed bevel gears available for unique applications?

Yes, many suppliers offer custom-designed bevel gears to meet specific requirements such as unusual gear ratios, special materials or coatings, or nonstandard sizes.

What should I consider when choosing a supplier for bevel gears?

When selecting a supplier for bevel gears, consider their manufacturing capabilities, quality assurance processes including machinery test reports provided, after-sales support services available, and whether they offer customized solutions like ODM/OEM services.

How does gear ratio impact the function of bevel gears in machinery?

The gear ratio determines the mechanical advantage offered by the gear set. It affects the output torque and speed; a higher gear ratio increases torque but reduces speed and vice versa.

Is it possible to repair or refurbish damaged bevel gears?

Depending on the extent of damage and gear material, it may be possible to repair or refurbish bevel gears. However, this should only be attempted by professionals with expertise in gear maintenance.

Can I specify the coating for my bevel gears?

Yes, many suppliers offer various coating options for corrosion resistance or improved wear characteristics. Options may include tin plating or other specialized coatings based on application needs.

What is micro machining in the context of bevel gears?

Micro machining refers to precision engineering practices used to create small-sized components or features on components with high precision. This process is often utilized for intricate designs or when high tolerances are required.

How do I ensure compatibility between my existing machinery and new bevel gears?

To ensure compatibility between your machinery and new bevel gears, it's essential to match specifications such as dimensions, tooth profile, pitch angle, material properties, and mounting requirements accurately.

Are there industry standards that govern the manufacturing of bevel gears?

Yes, there are various industry standards that apply to gear manufacturing including those from ISO (International Standards Organization), AGMA (American Gear Manufacturers Association), and DIN (German Institute for Standardization), which guide dimensional accuracy and quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4