Introduction to Beam Saws

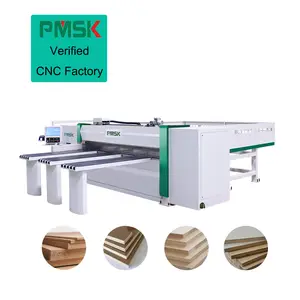

Beam saws, a vital tool in the woodworking and construction industries, stand out for their precision in cutting large panels and solid timber. These powerful machines are designed to handle heavy-duty tasks, effortlessly slicing through various materials to create uniform and accurate cuts. The efficiency of a beam saw is unparalleled when it comes to processing large volumes of wood, making it an indispensable asset for professionals.

Types and Applications

The versatility of beam saws is evident in the range of types available, such as the horizontal panel saw and the makita beam saw, each serving specific cutting needs. Horizontal panel saws are ideal for cutting large sheets of material with precision, while Makita's offerings are known for their portability and power. These saws are not just limited to wood; with the right blade, they can cut through materials like plastic and non-ferrous metals, making them a multi-industry tool.

Features and Materials

Modern beam saws incorporate advanced features that enhance their functionality. For instance, a beam cutter for circular saw transforms a standard circular saw into a beam cutting powerhouse. The construction of these saws often involves robust materials such as hardened steel and industrial-grade aluminum, ensuring longevity and consistent performance. The integration of features like laser guides and dust collection systems further augment their usability and precision.

Advantages of Using Beam Saws

The primary advantage of using a beam saw is its ability to deliver straight, precise cuts at a high production rate. Efficiency is boosted with features like programmable cutting patterns, which are particularly beneficial in models like the homag beam saw. Safety is another critical aspect, with manufacturers incorporating numerous safeguards to protect operators from potential hazards. The milwaukee beam saw is a testament to this, offering robust safety features alongside its powerful cutting capabilities.

Innovations in Beam Saw Design

Innovation in beam saw design focuses on energy efficiency and operator ease. The dewalt worm drive skill saw exemplifies this with its ergonomic design, reducing operator fatigue without compromising on power. Additionally, the skil worm drive circular saw is recognized for its energy-efficient operation, which contributes to lower operational costs without sacrificing performance.

Choosing the Right Beam Saw

Selecting the appropriate beam saw requires a careful assessment of your specific needs. Whether it's a beam cutter for skill saw for more intricate work or a heavy-duty skilsaw beam saw for larger projects, the right tool can significantly impact productivity and outcomes. For those requiring support structures, i beam saw horses offer a stable work platform, enhancing the overall cutting process. When choosing a beam saw, consider the material types, volume of work, and the desired precision to ensure you find a machine that aligns with your operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4