Introduction to Barb Wire Machines

Barb wire machines are essential equipment in the production of barbed wire, widely utilized in various industries for security and fencing purposes. These machines streamline the process of creating barbed wire, which is a type of steel fencing wire constructed with sharp edges or points arranged at intervals. The primary function of these machines is to ensure efficient production while maintaining the integrity of the wire's design.

Types and Applications

The versatility of barb wire machines is evident in their applications across different sectors. From agricultural fencing to security barriers in military and industrial settings, the produced wire fulfills numerous roles. In agriculture, it is used to construct fences that keep livestock within boundaries, while in security, it serves as a deterrent against trespassers. The type of machine selected often depends on the intended use of the barbed wire, with variations designed to cater to specific mesh sizes and durability requirements.

Features and Specifications

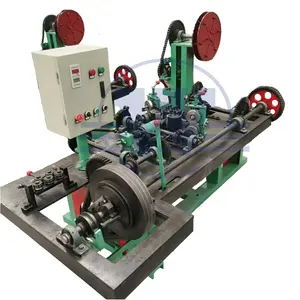

Barb wire machines come with a range of features tailored to the production demands. Key specifications include wire diameter, mesh width, and mesh hole size, which can be adjusted to meet specific needs. The machines are designed for ease of operation with a focus on automation to minimize the need for manual intervention, thereby enhancing productivity. The construction of these machines ensures the production of wire that is not only functional but also has a consistent finish.

Materials and Durability

The construction of barb wire machines involves materials that can withstand the rigors of wire production. Durability is a critical aspect, as these machines often operate under high stress to twist and cut steel wire. The robustness of the machine directly influences the longevity and quality of the barbed wire produced, ensuring that the end product can withstand environmental factors when used in fencing and security applications.

Advantages of Modern Barb Wire Machines

Modern barb wire machines offer several advantages, including increased production efficiency and operational safety. With advancements in technology, these machines have become more user-friendly and require less maintenance, leading to uninterrupted production cycles. The precision engineering involved in the design of barb wire machines ensures that the final product meets the required standards of strength and aesthetics, making them suitable for a wide range of uses from construction reinforcement to decorative applications.

Choosing the Right Machine

Selecting the appropriate barb wire machine is crucial for meeting production goals. Alibaba.com hosts a variety of machines, each designed to fulfill different aspects of barbed wire production. Prospective buyers can assess their needs against the features of each machine, ensuring that they choose a model that aligns with their production volume, desired wire characteristics, and operational capacity. While Alibaba.com facilitates this selection process, it is important to consider the technical specifications and performance capabilities of each machine to make an informed decision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4