Alibaba.com showcases a diverse range of bamboo cutting machines to cater to various woodworking requirements. Among the selection, you'll find CO2 laser cutters and engravers that are versatile for cutting and engraving on bamboo, wood, acrylic, and even glass. These machines come with different power options, such as 60w to 150w, and often include a rotary function for handling cylindrical objects like wine bottles.

For those involved in the lumber industry or needing to process larger wood pieces, there are diesel engine powered wood chipper shredders and branch chipping machines. These are ideal for converting large branches into smaller chips. Panel cutting saws and wood pallet blocks cutting machines are also available, designed for precise cutting of wood panels and pallet blocks respectively.

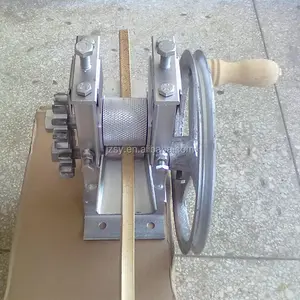

The range extends to specialized bamboo processing equipment, including automatic bamboo splitting, breaking, and cutting machines. These are engineered for efficient splitting and cutting of bamboo sticks, with some models designed for one-time forming of bamboo cross sticks. Additionally, there are manual and small hand-operated bamboo flake cutters, splitter knives, and mini bamboo splitting machines for more intricate or smaller scale operations.

For the production of bamboo skewers, sticks for agarbatti, and toothpicks, there are machines tailored to these specific outputs. These include bamboo stick making machines, toothpick making machines, and bamboo wool slicers, which are designed to produce uniform and precise cuts, essential for quality end products. The availability of automatic toothpick and skewer sharpening machines as part of the production line ensures a complete solution for bamboo stick preparation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4