Introduction to Aluminum Square Tube Connectors

Aluminum square tube connectors are integral components in the construction of robust and versatile pipe systems. These connectors serve as pivotal junctions in both commercial and residential settings, facilitating the assembly and stability of square aluminum tubing frameworks. The choice of aluminum for these connectors is due to its inherent properties, such as its strength-to-weight ratio and resistance to corrosion, making it an ideal material for sustaining long-lasting pipe systems.

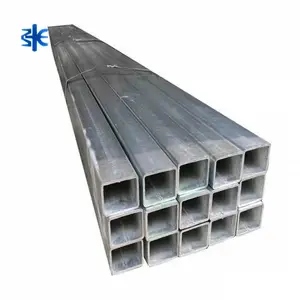

Types and Applications

The applications of aluminum square tube connectors are diverse, ranging from supporting frameworks in construction to intricate designs in custom furniture. In industrial settings, these connectors are used to construct sturdy frames for equipment or storage racks. Residentially, they might be found in the assembly of modern pergolas or lightweight fencing. The versatility of these connectors is enhanced by the variety of types available, each designed to meet specific angular and load-bearing requirements.

Features and Advantages

When considering the features of aluminum square tube connectors, their compatibility with various aluminum square tubing sizes stands out. This ensures a secure fit and ease of assembly. The connectors are designed with precision to maintain the integrity of the tube's shape and provide a seamless connection point. The advantages of using aluminum connectors include their resistance to environmental wear and tear, which is particularly beneficial for outdoor applications. Additionally, their lightweight nature eases transportation and handling during the construction process.

Material Specifications

The material composition of aluminum square tube connectors is crucial as it dictates the connector's durability and suitability for different environments. Aluminum's non-magnetic quality and thermal conductivity are also factors that make it a preferred material in various applications. The connectors are often treated or anodized to enhance their resistance to corrosion and wear, further extending their service life.

Design Considerations

In the design of aluminum square tube connectors, attention is paid to the ease of installation and the ability to withstand the mechanical stresses of the system. The connectors are engineered to ensure a secure connection without the need for excessive hardware, which can streamline the assembly process and reduce additional material costs. The aesthetic appeal of aluminum connectors is not overlooked, with their sleek finish contributing to a clean and professional look in visible applications.

Choosing the Right Connector

Selecting the appropriate aluminum square tube connector is dependent on the specific requirements of the project. Factors such as the dimensions of the square tubing, the expected load, and environmental conditions play a significant role in the decision-making process. It is important to consider the compatibility of the connector with the type of aluminum tubing being used to ensure a secure and reliable assembly.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4