Understanding Actuators

Actuators are fundamental components in modern machinery, playing a pivotal role in motion control systems. They serve as the driving force behind a multitude of devices, converting electrical energy into mechanical torque. This category encompasses a variety of models, including electric actuators, pneumatic actuators, and hydraulic actuators, each designed to meet specific operational needs.

Types and Applications of Actuators

The diversity of actuators allows for their application across various industries. Motor operated valves are commonly integrated with actuators to regulate fluid flow in industrial settings. In precision agriculture, linear actuators are employed to control machinery with exactitude. The versatility of actuators extends to healthcare, where they are instrumental in medical devices, and to home automation, where IoT actuators are becoming increasingly prevalent.

Features of Different Actuators

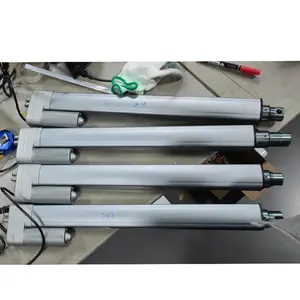

Each actuator type boasts unique features. Linear electric motors offer precise linear motion, ideal for applications requiring accuracy. Pneumatic cylinder systems, including pneumatic air cylinders, pneumatic ram cylinders, and pneumatic piston cylinders, provide robust force output and are valued for their speed and efficiency. Rotary actuators are sought after for their compact design and are capable of delivering high torque in limited spaces.

Materials and Advantages

Actuators are constructed from materials that ensure durability and longevity. Metals such as aluminum and steel are common for their strength and resistance to harsh environments. The advantages of using actuators include enhanced precision in control systems, improved energy efficiency, and the ability to operate in challenging conditions without significant wear and tear.

Selecting the Right Actuator

Choosing the correct actuator involves considering the application's specific requirements. Factors such as load, speed, travel length, and environment are critical. For instance, a motorized actuator might be ideal for heavy-duty operations, while a belimo actuator could be better suited for HVAC applications. It is essential to review the specifications of each actuator motor to ensure compatibility with the intended use.

Integration and Compatibility

Integrating actuators into existing systems requires an understanding of the various types of actuators and their compatibility with other components, such as valves and actuators. It is crucial to ensure that the chosen actuator aligns with the mechanical and electrical requirements of the application to achieve optimal performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4