Exploring the Versatility of Acrylic Machine Covers

Acrylic machine covers are integral components in various industries, offering protection and clarity. These covers are crafted from durable acrylic, known for its strength and transparency, making them ideal for safeguarding machinery while allowing visibility.

Types and Applications of Acrylic Covers

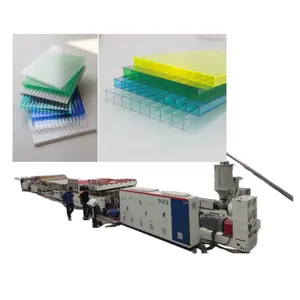

Acrylic covers come in multiple forms, each serving specific applications. Thermoformed acrylic covers are prevalent in industries where complex shapes are required, whereas flat acrylic guards are common in environments that demand straightforward, flat protection. These covers are not limited to industrial use; they also play a role in consumer products, such as in electronics, where they provide a clear, protective interface.

Features and Advantages of Acrylic Covers

The features of acrylic machine guards include their high impact resistance and clarity. These properties are essential in environments where both protection and visibility are paramount. The advantage of using acrylic is its versatility and adaptability to various manufacturing processes, including vacuum forming, which allows for detailed and precise shapes.

Material Specifications and Sustainability

Acrylic, a thermoplastic with a reputation for durability, is the primary material for these covers. It is favored for its recyclability and ability to be reshaped at high temperatures, contributing to sustainable manufacturing practices. Custom acrylic enclosures can be designed to meet specific environmental and operational requirements, ensuring both functionality and eco-friendliness.

Design Considerations for Acrylic Machine Covers

When designing acrylic protective covers, considerations include the thickness of the material, the complexity of the shape, and the type of acrylic used. These factors determine the cover's durability and suitability for the intended application. Designers often opt for clear acrylic covers for their neutral appearance and compatibility with a wide range of machine aesthetics.

Choosing the Right Acrylic Cover for Your Needs

Selecting the appropriate acrylic machine cover involves assessing the operational environment, the level of protection required, and the specific machinery dimensions. It is crucial to consider the cover's resistance to chemicals, heat, and impact to ensure it meets the demands of its application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4