Exploring the Capabilities of a 9 Axis Controller

The realm of CNC machining is revolutionized by the integration of sophisticated controllers, with the 9 axis controller standing at the forefront of this technological advancement. This category represents a pinnacle in precision and versatility for automated manufacturing tasks, applicable across diverse industries. A 9 axis controller orchestrates the movements and operations of CNC machines, enabling the execution of intricate designs and enhancing the functionality of both new and retrofitted equipment.

Types and Applications of 9 Axis Controllers

Controllers are not a one-size-fits-all solution; they vary greatly to meet specific needs. The 9 axis CNC controller is particularly adept for complex machinery, including lathes, mills, and grinders. Its application is crucial in tasks requiring multi-axis coordination, such as aerospace part fabrication, automotive manufacturing, and intricate prototyping. By facilitating operations on nine different axes simultaneously, these controllers allow for the creation of detailed and complex geometries that were previously unattainable.

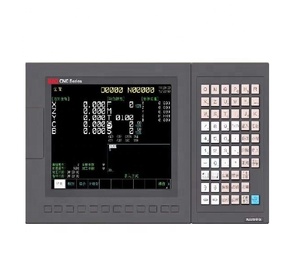

Features and Materials of 9 Axis Controllers

A 9 axis CNC machine controller is characterized by its robust construction and advanced features. Typically made from durable materials capable of withstanding the rigors of industrial environments, these controllers boast high-speed processing capabilities and are equipped with interfaces that support various programming languages. The adaptability of these controllers means they can be integrated with existing systems, enhancing their performance and extending their operational life.

Advantages of Utilizing a 9 Axis Controller

The advantages of employing a 9 axis control system are manifold. Precision is significantly heightened, allowing for the production of components with extremely tight tolerances. Efficiency is another key benefit, as these controllers streamline the manufacturing process by reducing the need for multiple setups. This not only saves time but also minimizes the potential for errors, resulting in a more reliable production process.

Complementary Components and Kits

In addition to standalone controllers, the market offers a variety of complementary components such as stepper motors, which enhance the torque and precision of CNC machines. For those inclined towards customization, controller kits are available, providing all necessary components to tailor machinery to specific requirements. These kits empower users to harness the full potential of their CNC 9 axis controller, ensuring that their machinery is perfectly suited to the task at hand.

Choosing the Right 9 Axis Controller

Selecting the appropriate 9 axis controller is crucial for optimizing CNC machine performance. Prospective buyers should consider the compatibility of the controller with their existing machinery, the type of tasks they wish to perform, and the level of precision required. With a comprehensive selection available, finding a controller that aligns with the specific needs of a business is streamlined, ensuring that any investment into a 9 axis CNC controller is a step towards greater productivity and precision in manufacturing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4